Material Testing of Existing Structures

Renovation projects are often complex endeavors in which engineers often lack pertinent structural information of the original design and any subsequent changes to the building. Investigating old records from previous owners, historical resources and searching for photographs taken during construction can be helpful; however, engineers typically need more definitive material specifications to ensure the capacity of the system can sustain new intended loads for the structure.

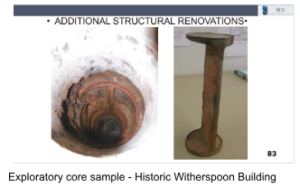

In the April 2023 SEU session, D. Matthew Stuart, PE, SE, P.Eng, F.ASCE, F.SEI, A.NAFE, from Partner Engineering and Science, Inc., presented Adaptive Reuse of the Historic Witherspoon Building. Matthew reviewed the different types of vintage structural components used at the historic Witherspoon building in Philadelphia, PA. He explained the different approaches used to determine the load carrying capacity of the existing floor and roof framing and talked about the historical reasons for the development and use of hollow clay tile arch framing systems.

Due to the age of the structure and lack of construction documents, the steel used on the project was tested to determine the actual yield strength to be used in the renovation design. After the presentation, Matthew was asked for guidance on coupon testing steel from an existing structure, and he provided some tips for successfully determining the yield strength.

Matthew noted that a steel coupon test only needs a sample about 2 inches wide and 6-8 inches long to perform the load test. Typically, the steel can be safely collected from redundant areas of the structure such as the bottom flange of a simply supported beam near the support or the bottom chord extension of an open web steel joist. Exploratory demolition may also be necessary to locate structural systems hidden behind walls or ceilings.

Lab testing can then be performed to determine the yield strength of the steel. Typical testing standards include ASTM A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products or ASTM E8 Standard Test Methods for Tension Testing of Metallic Materials at room temperature.

Lab testing can then be performed to determine the yield strength of the steel. Typical testing standards include ASTM A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products or ASTM E8 Standard Test Methods for Tension Testing of Metallic Materials at room temperature.

It is common during reuse or renovation projects to be without necessary design information from the original construction. While educated design assumptions based on historical data must be used, material lab testing ensures designers do not use overly conservative assumptions, and can maximize the capacity of the structural system being repurposed.

There are no comments yet, but you can be the first