Steel Deck: Finish or Coating?

When should steel deck be galvanized versus shop coated? Does one finish provide more protection than the other? And what considerations should impact which deck type to select?

In the September 2025 SEU session, Joshua Canova, PE, from New Millennium, and Victor Esty, from Canam Steel Corporation, presented Properly Specifying Steel Deck. Joshua and Victor identified resources that are available to help specify steel deck and reviewed the design considerations for selecting steel deck profiles. They highlighted proper expectations of steel deck finish performance and appearance, and described what to avoid when specifying steel deck.

Josh reviewed the available options for steel deck finishes and coatings. As you can see in the slide below, there are 5 options to explore when specifying steel deck, depending on the use, function, and environment of the structure.

Bare deck can be used in roof deck, form deck, or composite deck floors. As the name implies, the deck is bare and does not have any protective coating applied. A bare deck is more prone to the deleterious effects of water or caustic chemicals in the environment, but may be entirely appropriate for indoor and well protected decks.

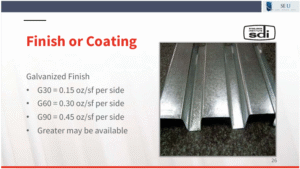

Galvanized deck is a carbon steel deck that has been finished with a zinc coating which protects the steel from rust by acting as a sacrificial barrier between moisture and the steel. Galvanized steel deck is typically available in G30, G50, or G90, which denotes the amount of zinc applied per square foot as shown in the slide below. Galvanized steel is the most common specified steel deck, especially in outdoor or moisture-rich environments. Galvanized deck may be used in roof, form, or composite decks. Touch up with zinc-rich paint may be required where damage to the finish occurs in the field, but is not usually necessary for small nicks or scratches. Galvanized deck is more expensive than bare deck and about 20% more than a shop coated deck. Galvalume is a similar product, typically used in roofing applications, which consists of carbon steel hot-dipped with layers of zinc and aluminum to achieve a durable and corrosion resistant deck.

Shop coated deck refers to carbon steel deck that has been painted with a primer. Typically gray and/or white primer is available, although some manufacturers may offer other colors. The shop applied primer is intended to act as the barrier to protect the steel, but a final field applied paint should be used when necessary for aesthetic purposes. Galvanized deck can also be shop coated to provide additional protection and a more aesthetic finish. Roof, form, and composite deck are all available with a shop coated primer, however, it is important to note that the top side of composite deck should not be specified to be shop coated. The composite action of the concrete and deck cannot be achieved with a shop coated steel, as the coating allows for slippage to occur between the deck and the concrete.

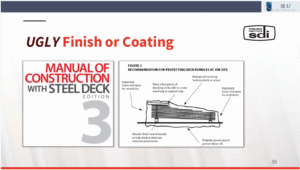

All steel deck should be protected when stored on job sites to prevent environmental damage. As you can see in the slide below, the deck should be covered, elevated, and sloped to allow air flow and moisture flow, to prevent rust or staining from occurring.

The structural engineer should also consider other options when the deck will be used in corrosive environments. This could include some agricultural, industrial, or high humidity environments, as well as exposure to chemicals such as chlorine, acids, or ammonia. Steel decks exposed to these corrosive environments should be well protected by the addition of barriers or coatings, or the engineer should consider stainless steel. Also, ventilation will be critical to minimizing the deleterious effects in a corrosive environment.

Properly specifying steel deck is critical to ensuring an appropriate life cycle of the deck. A deck which has not been protected with finishes or coatings could lead to unwanted corrosion and reduce the load capabilities of the deck. Engineers should consider the use, function, and environment in which the deck will be exposed before specifying criteria for the coating or finish of the steel deck.

There are no comments yet, but you can be the first