Retrofit Strategies for Flat Plate Construction

The recent collapse of the Champlain Towers South structure has put a spotlight on the danger of progressive collapse and the sudden nature of punching shear failures. Do you know the signs of a punching shear deficiency in flat-plate construction? How can these types of failures be identified and repaired?

In the October 2024 SEU Session, Matthew Fadden, PhD, PE, from WJE, and Andrea Shear, PE, from Murray Engineering, presented Identifying, Evaluating, and Correcting Punching Shear Deficiencies in Flat Plate Construction. Matt and Andrea shared several examples of punching shear related building failures. They explained how to calculate the expected punching shear strength of flat plates considering the flexural reinforcing and slab thickness, and how to assess a structure for signs of punching shear related distress. Andrea then shared ways to correct a punching shear deficiency and ways to retrofit structures in distress.

Punching shear deficiencies often alert their presence with radial cracks, but are not entirely unique compared to typical flexural cracking. Concerning cracks should always be investigated to ensure the slab meets the intended design and is free from construction flaws, and the cracks should be repaired on any slabs which may be exposed to moisture. Once a punching shear deficiency is identified by distress and analysis, repairs can be made to prevent a sudden failure from occurring.

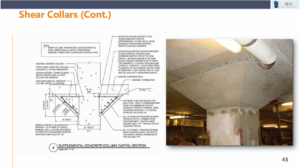

Andrea offered three solutions to retrofit structures found to have punching shear deficiencies. Shear collars are an efficient way to increase shear strength of a flat plate. During installation, the surface of the existing column is roughened, and hoop reinforcement is added to confine the new concrete addition. This combination of a roughened surface along with the confining collar provides a significant increase in shear strength to the flat plate slab and also decreases the clear span of the slab. As shown below, shear collars or column capitals dowel into the existing column without encroaching too much into the floor to ceiling height throughout the structure.

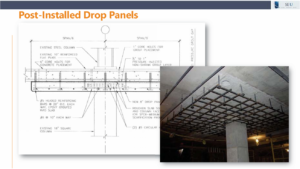

The second solution to retrofit punching shear deficiencies are the addition of drop panels with or without shear collars, as shown below. The addition of drop panel reinforcement increases the ‘d’ depth of the shear strength calculation, as well as the depth to the negative reinforcement. Existing surface cracks should be repaired and epoxy injected, and core holes are drilled into the slab to allow the concrete to be pumped into the formed drop panel below the existing slab. The additional reinforcing bars are added in both directions and help control flexural cracking which can prevent water intrusion into the slab causing unwanted corrosion. Drop panels do encroach some on the floor to ceiling height, but they still offer a reasonable option to increase the flexural and shear capacity of the flat plate slab system.

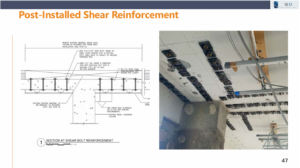

A third option which Andrea offered as a solution for flat plates needing additional shear capacity is the addition of post-installed shear thru-bolt reinforcement. This option should not be used as a retrofit option on structures showing distress from reinforcement deficiencies. However, the shear bolt option can be used to increase the shear capacity for flat-plate slab construction to resist additional loads beyond the original design capacity. As shown below, holes are drilled and threaded rods set in a proprietary adhesive product are added near the column support to increase the shear capacity. Andrea noted that once shear reinforcement is provided, the engineer can no longer use the full shear capacity of the concrete, thus enough bolts would need to be added to replace the lost shear contribution from the concrete and then increased from there to actually improve the shear performance of the slab. Engineers may also utilize radar to avoid interference with existing reinforcement in the slab, so the new shear bolts may not be uniformly spaced. After installation, the thru-bolts may need to be protected from fire, since they are exposed and no longer protected by the concrete slab.

While flat-plate construction is common and useful, it can be susceptible to construction defects which can lead to punching shear deficiencies and failures. Punching shear failures are particularly devastating due to the brittle and sudden nature of the failure and can lead to progressive collapse of the structure or portions thereof. There are efficient solutions to structures showing signs of punching shear distress including shear collars and drop panels, and slabs needing additional load carrying shear capacity can be improved with shear bolts.

There are no comments yet, but you can be the first