26 Feb / 2026

“SEU Speaker Inspires” Organization of the Month: Thomas M. Murray Structures Laboratory at Virginia Tech

In August 2025, SEU welcomed Joe Pote, PE, from New Millennium, and Dave Samuelson, PE, retired from Nucor, to present Composite Floor Joist Systems. Joe and Dave have designated the Thomas M. Murray Structures Laboratory at Virginia Tech (Home | Structural Engineering and Materials | Virginia Tech) for our SEU Speaker Inspires donation for the month.

Joe and Dave shared, “Dr. Thomas M. Murray was instrumental in coordinating steel joist research documenting the behavior of the Steel Joist Institute’s CJ-Series composite steel joists and floor vibration of steel joist supported concrete floor systems. With Dr. Murray’s recent passing in August 2024, it is appropriate to honor the Thomas M. Murray Structures Laboratory for completing the above-mentioned steel joist research as well as continuing research of steel structures. Thanks to Dr. Murray’s vision, the Thomas M. Murray Structures Lab continues to be used for structural research, and we continue to build on the foundational research performed by Dr. Murray.”

Thank you, Joe and Dave, for helping structural engineers with your SEU session, and for your designation of Thomas M. Murray Structures Laboratory at Virginia Tech as our SEU Speaker Inspires Organization of the Month!

SEU began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SEU to make a donation to help improve our world.

26 Feb / 2026

PT Design Resources

Are you just getting started on a new post-tensioning design project? Are you able to quickly establish some basic slab thickness guidelines early on in your PT projects, or are you looking for great resources to guide the early schematic design phase of your projects?

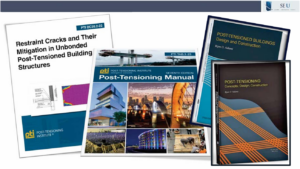

In the December 2025 SEU session, Carine Leys, from WSP, presented The Design Arc of Post-Tensioning. Carine explained how to evaluate during the conceptual phase if post-tensioning is a structural solution that meets the project’s performance requirements. She reviewed ways to develop comprehensive documentation relevant to each phase of the project and identified best practices during construction to ensure safety and durability.

Carine offered several resources for PT design as shown on the slide below. These include Restraint Cracks and Their Mitigation in Unbonded Post-Tensioned Building Structures from PTI. This document provides details and considerations for pour strip placements, duration of pour strips, and details to mitigate cracks. Carine also recommends the Post-Tensioning Manuel, Seventh Edition, from PTI. This reference is excellent for early preliminary sizing and examples to use without having to do much analysis, especially early on in the schematic phase of a project. This is especially useful if the engineer does not yet have years of experience with PT design.

The two additional resources Carine mentioned are Post-Tensioned Buildings Design and Construction and Post-Tensioning Concepts; Design; Construction, both by Bijan O. Aalami. These references are useful and practical for the design engineer during the design and construction phase of PT projects.

SEU / SE Solutions is pleased to support two charitable organizations in 2025 which directly support children and families in Lisa’s local community as well as across the country. Lisa selected Goods4Greatness and Food Share Ventura County to receive these donations, and we are thankful to our SEU community for making this community support possible.

SEU / SE Solutions is pleased to support two charitable organizations in 2025 which directly support children and families in Lisa’s local community as well as across the country. Lisa selected Goods4Greatness and Food Share Ventura County to receive these donations, and we are thankful to our SEU community for making this community support possible.

Lisa shared, “As a parent, I fully believe kids need to have “their thing,” whether that is playing an instrument, doing volunteer work, or participating in a sport. About 10 years ago, I was the President of a Youth Track Club, and I saw how many families were asking for help with league fees. At the same time, I saw how expensive it was to buy equipment for different teams – and that’s just for shoes (basketball shoes, soccer cleats, baseball cleats, spikes)! I worried about the kids who weren’t able to afford to participate, and hated the idea that cost was a barrier to sports. I had the idea of creating an organization to help kids afford sports equipment and league fees, but as I searched the internet for ideas, I found Goods4Greatness. It was started by a sports reporter who used to write for our local newspaper, and although she had moved across the country, she still supported our local schools and leagues, helping buy Balls, Racquets, Shoes, etc. for kids who wouldn’t otherwise be able to afford it. I love seeing the impact that G4G is able to make locally, and across the country.” To learn more about Goods4Greatness, visit their website to see the change they are making across our country.

Regarding Food Share, Lisa said, “Food Share helps local families in Ventura County by distributing over one million pounds of food per month, operating food pantry sites, drive through food pick-up, hot meal locations, and more. Especially in times when food costs are rising, leading to more families feeling the pressure of being able to afford nutritious food, Food Share provides options, in their own words, “Because no one should go hungry,” and I’m grateful for the work they do in our community.” To learn more about Food Share, visit their website to see their impact in Ventura County.

Regarding Food Share, Lisa said, “Food Share helps local families in Ventura County by distributing over one million pounds of food per month, operating food pantry sites, drive through food pick-up, hot meal locations, and more. Especially in times when food costs are rising, leading to more families feeling the pressure of being able to afford nutritious food, Food Share provides options, in their own words, “Because no one should go hungry,” and I’m grateful for the work they do in our community.” To learn more about Food Share, visit their website to see their impact in Ventura County.

SEU / SE Solutions is proud to support these charitable organizations and look forward to making a bigger impact for good in our country in 2026.

In July 2025, SE University welcomed Erica Fisher, PhD, PE, from Oregon State University, to present Hot Topic: The Fire Performance of Mass Timber. Previously in 2021, Erica designated the Girls Build (https://girlsbuild.org/) for our SEU Speaker Inspires donation for the month and she has chosen to do the same in 2025.

Erica shared “Girls Build provides access and opportunity for young girls to engage with the building construction industry through hands-on learning experiences in the state of Oregon. These types of experiences can change the perception young girls have of the building construction industry and the perception of what careers are possible for them. As engineers, it is critical that we have diversity within our offices so that we can create solutions to societal issues that are applicable to all members of a community.”

Thank you, Erica, for helping structural engineers with your SE University session, and for your designation of Girls Build as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

21 Jan / 2026

ACI 318-19(22) – Development Length of Deformed Bars when using Higher Yield Strength Reinforcement

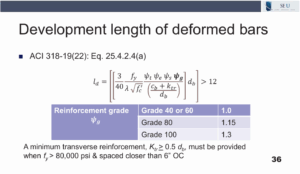

In the October 2025 SEU session, Kimberly Kramer, PhD, PE, from Kansas State University, presented Navigating the ACI 318-19(22) Code: Practical Implications for Structural Engineers. Kimberly described how ACI 318-19(22) can be used for shear design, two-way slab provisions, anchoring to concrete, and basic seismic detailing of special structural walls. She noted the technical rationale behind the code and its broader impact on structural safety, resilience, and constructability.

During the session, Kimberly highlighted the equation for the development length of deformed bars. As you can see in the slide below, Equation 25.4.2.4(a) includes the Reinforcement grade factor 𝝍g, which was first introduced into the code in the ACI 319-19. Research has shown that higher grades of steel reinforcement require an increased development length. Also, a minimum transverse reinforcement must be provided when the yield strength is greater than 80,000 psi and must be spaced closer than 6 inches on center. The transverse reinforcement aims to reduce the possibility of a splitting failure due to the higher yield stresses in the longitudinal reinforcement.

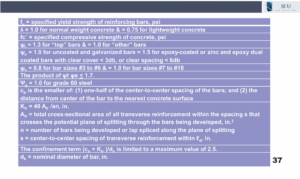

All other variables of Eq. 25.4.2.4(a) are the same as in past versions of ACI 318. As you can see in the slide below, these variables include factors for yield strength, concrete strength and type, as well as bar size, location, and spacing factors.

The addition of the Reinforcement Grade Factor, along with the minimum transverse reinforcement for fy > 80,000 psi, aims to rectify unconservative estimates for the development length of deformed bars when using higher grades of steel. ACI 318-19(22) has noted the results of research for higher grades of reinforcing steel, and using these new values for the reinforcement grade factor 𝝍g, the development length of bars may increase upwards of 50% or more. Thus, engineers should be aware of the implications of using higher grades of steel and the resulting increase in the development length for deformed bars.

29 Dec / 2025

“SEU Speaker Inspires” Organization of the Month: Institute of Science Tokyo International Exchange Support Project

In June 2025, Ben Sitler, PE, SE, from Buro Happold, presented Seismic Design with BRBs – Pushing to the Limit. He nominated Institute of Science Tokyo International Exchange Support Project (https://www.titech.ac.jp/english/public-engagement/giving/recognition/study-abroad) for the SEU Speaker Inspires donation of the month.

Ben shared, “The International Exchange Support Project fund at Science Tokyo promotes collaboration between Japan and overseas academics. The US and Japan have always had a rich spirit of collaboration, and I personally gained a tremendous amount from studying and working in Japan, given its unique structural design approaches. This donation is to help support the next generation.”

Thank you, Ben, for helping structural engineers with your SE University session, and for your designation of Institute of Science Tokyo International Exchange Support Project as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

29 Dec / 2025

Retrofit Strategies for Flat Plate Construction

The recent collapse of the Champlain Towers South structure has put a spotlight on the danger of progressive collapse and the sudden nature of punching shear failures. Do you know the signs of a punching shear deficiency in flat-plate construction? How can these types of failures be identified and repaired?

In the October 2024 SEU Session, Matthew Fadden, PhD, PE, from WJE, and Andrea Shear, PE, from Murray Engineering, presented Identifying, Evaluating, and Correcting Punching Shear Deficiencies in Flat Plate Construction. Matt and Andrea shared several examples of punching shear related building failures. They explained how to calculate the expected punching shear strength of flat plates considering the flexural reinforcing and slab thickness, and how to assess a structure for signs of punching shear related distress. Andrea then shared ways to correct a punching shear deficiency and ways to retrofit structures in distress.

Punching shear deficiencies often alert their presence with radial cracks, but are not entirely unique compared to typical flexural cracking. Concerning cracks should always be investigated to ensure the slab meets the intended design and is free from construction flaws, and the cracks should be repaired on any slabs which may be exposed to moisture. Once a punching shear deficiency is identified by distress and analysis, repairs can be made to prevent a sudden failure from occurring.

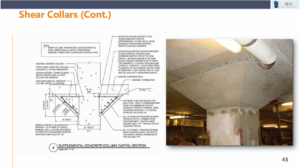

Andrea offered three solutions to retrofit structures found to have punching shear deficiencies. Shear collars are an efficient way to increase shear strength of a flat plate. During installation, the surface of the existing column is roughened, and hoop reinforcement is added to confine the new concrete addition. This combination of a roughened surface along with the confining collar provides a significant increase in shear strength to the flat plate slab and also decreases the clear span of the slab. As shown below, shear collars or column capitals dowel into the existing column without encroaching too much into the floor to ceiling height throughout the structure.

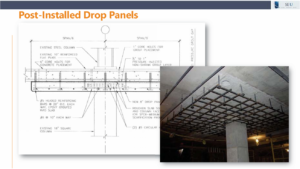

The second solution to retrofit punching shear deficiencies are the addition of drop panels with or without shear collars, as shown below. The addition of drop panel reinforcement increases the ‘d’ depth of the shear strength calculation, as well as the depth to the negative reinforcement. Existing surface cracks should be repaired and epoxy injected, and core holes are drilled into the slab to allow the concrete to be pumped into the formed drop panel below the existing slab. The additional reinforcing bars are added in both directions and help control flexural cracking which can prevent water intrusion into the slab causing unwanted corrosion. Drop panels do encroach some on the floor to ceiling height, but they still offer a reasonable option to increase the flexural and shear capacity of the flat plate slab system.

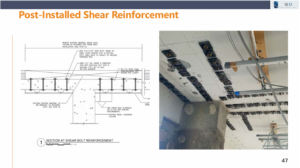

A third option which Andrea offered as a solution for flat plates needing additional shear capacity is the addition of post-installed shear thru-bolt reinforcement. This option should not be used as a retrofit option on structures showing distress from reinforcement deficiencies. However, the shear bolt option can be used to increase the shear capacity for flat-plate slab construction to resist additional loads beyond the original design capacity. As shown below, holes are drilled and threaded rods set in a proprietary adhesive product are added near the column support to increase the shear capacity. Andrea noted that once shear reinforcement is provided, the engineer can no longer use the full shear capacity of the concrete, thus enough bolts would need to be added to replace the lost shear contribution from the concrete and then increased from there to actually improve the shear performance of the slab. Engineers may also utilize radar to avoid interference with existing reinforcement in the slab, so the new shear bolts may not be uniformly spaced. After installation, the thru-bolts may need to be protected from fire, since they are exposed and no longer protected by the concrete slab.

While flat-plate construction is common and useful, it can be susceptible to construction defects which can lead to punching shear deficiencies and failures. Punching shear failures are particularly devastating due to the brittle and sudden nature of the failure and can lead to progressive collapse of the structure or portions thereof. There are efficient solutions to structures showing signs of punching shear distress including shear collars and drop panels, and slabs needing additional load carrying shear capacity can be improved with shear bolts.

In May 2025, Kyle Jenkins, PE, from Advantage Structural Engineers, presented Tips for the EOR when Delegating Steel Connection Design. He nominated Cincinnati Off-Road Alliance (CORA – Cincinnati Off-Road Alliance) for the SEU Speaker Inspires donation of the month.

Kyle shared, “CORA builds and maintains natural surface trails in the Cincinnati region, for mountain biking, hiking, and running. The ability to escape the office and quickly get into the forest has been my vital to my work life balance and mental health. I believe urban forests and trails are vital to the mental and physical health of cities and their residents. I encourage everyone to support their local parks and trails.”

Thank you, Kyle, for helping structural engineers with your SE University session, and for your designation of Cincinnati Off-Road Alliance as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

30 Nov / 2025

Steel Deck: Finish or Coating?

When should steel deck be galvanized versus shop coated? Does one finish provide more protection than the other? And what considerations should impact which deck type to select?

In the September 2025 SEU session, Joshua Canova, PE, from New Millennium, and Victor Esty, from Canam Steel Corporation, presented Properly Specifying Steel Deck. Joshua and Victor identified resources that are available to help specify steel deck and reviewed the design considerations for selecting steel deck profiles. They highlighted proper expectations of steel deck finish performance and appearance, and described what to avoid when specifying steel deck.

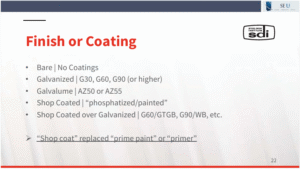

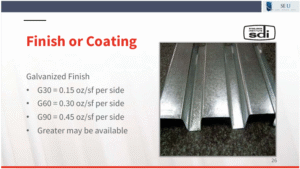

Josh reviewed the available options for steel deck finishes and coatings. As you can see in the slide below, there are 5 options to explore when specifying steel deck, depending on the use, function, and environment of the structure.

Bare deck can be used in roof deck, form deck, or composite deck floors. As the name implies, the deck is bare and does not have any protective coating applied. A bare deck is more prone to the deleterious effects of water or caustic chemicals in the environment, but may be entirely appropriate for indoor and well protected decks.

Galvanized deck is a carbon steel deck that has been finished with a zinc coating which protects the steel from rust by acting as a sacrificial barrier between moisture and the steel. Galvanized steel deck is typically available in G30, G50, or G90, which denotes the amount of zinc applied per square foot as shown in the slide below. Galvanized steel is the most common specified steel deck, especially in outdoor or moisture-rich environments. Galvanized deck may be used in roof, form, or composite decks. Touch up with zinc-rich paint may be required where damage to the finish occurs in the field, but is not usually necessary for small nicks or scratches. Galvanized deck is more expensive than bare deck and about 20% more than a shop coated deck. Galvalume is a similar product, typically used in roofing applications, which consists of carbon steel hot-dipped with layers of zinc and aluminum to achieve a durable and corrosion resistant deck.

Shop coated deck refers to carbon steel deck that has been painted with a primer. Typically gray and/or white primer is available, although some manufacturers may offer other colors. The shop applied primer is intended to act as the barrier to protect the steel, but a final field applied paint should be used when necessary for aesthetic purposes. Galvanized deck can also be shop coated to provide additional protection and a more aesthetic finish. Roof, form, and composite deck are all available with a shop coated primer, however, it is important to note that the top side of composite deck should not be specified to be shop coated. The composite action of the concrete and deck cannot be achieved with a shop coated steel, as the coating allows for slippage to occur between the deck and the concrete.

All steel deck should be protected when stored on job sites to prevent environmental damage. As you can see in the slide below, the deck should be covered, elevated, and sloped to allow air flow and moisture flow, to prevent rust or staining from occurring.

The structural engineer should also consider other options when the deck will be used in corrosive environments. This could include some agricultural, industrial, or high humidity environments, as well as exposure to chemicals such as chlorine, acids, or ammonia. Steel decks exposed to these corrosive environments should be well protected by the addition of barriers or coatings, or the engineer should consider stainless steel. Also, ventilation will be critical to minimizing the deleterious effects in a corrosive environment.

Properly specifying steel deck is critical to ensuring an appropriate life cycle of the deck. A deck which has not been protected with finishes or coatings could lead to unwanted corrosion and reduce the load capabilities of the deck. Engineers should consider the use, function, and environment in which the deck will be exposed before specifying criteria for the coating or finish of the steel deck.

30 Nov / 2025

Happy Thanksgiving from SE Solutions!

We would like to take this opportunity to thank our SE Solutions community and hope everyone enjoyed a wonderful Thanksgiving holiday. SE Solutions and SEU are thankful to our clients and speakers who have made it possible for us to contribute to many charitable organizations during the past year through our SEU Speaker Inspires program.