In the immediate aftermath of the Northridge earthquake in 1994, steel buildings seemed to perform well. In the weeks to months following, however, extensive damage was found in special moment frame steel systems. As a result, FEMA allocated 10 million dollars to investigate, test and analyze materials, member connections, and structural systems in order to establish a better understanding of seismic structural systems, and recommend changes to building codes.

In the September 2019 SE University session, James O. Malley, SE, from Degenkolb Engineers, presented Changes to the Seismic Design of Steel Buildings. Jim reviewed how the damage caused to steel moment frames during the Northridge earthquake led to major changes in the design of steel structures. Jim outlined the new overall design philosophy which aims to develop inelastic mechanisms within designated structural fuses to dissipate the majority of the earthquakes energy. Jim also covered how seismic design requirements aim to satisfy this new design philosophy for the various structural systems.

During the session, Jim explained new language that was added in 2016 to AISC 341 in regard to columns that are common to intersecting frames. Research showed that in high R factor systems where columns are shared by intersecting frames, the 100/30 rule may not be adequate, especially for low rise buildings. Thus, language was added to ensure this potential simultaneous inelasticity is considered during design. In the 3 minute video below, Jim explains the reasoning for this code change.

24 Sep 2019

“SEU Speaker Inspires” Organization of the Month: The Land Conservancy of San Luis Obispo County

In July 2019, SE University welcomed John Lawson, PE, SE, from Cal Poly – San Luis Obispo, to present Engineering Tilt-Up: Design Provisions Born from Past Experience. John designated The Land Conservancy of San Luis Obsipo County (www.lcslo.org) for the SEU Speaker Inspires donation of the month.

John shared that he made this selection because: “I love this local organization as it preserves important open space and natural habitats while developing an educational outreach program called Learning Among the Oaks for elementary school children that fosters leadership and stewardship.”

Thank you, John, for helping structural engineers with your SE University session, and for your designation of The Land Conservancy of San Luis Obispo County as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

24 Sep 2019

Welding on In-Place Embed Plates

AISC’s Steel Solutions Center frequently receives questions related to welding in situations that are not ordinary or where special fixes are needed after something has gone wrong. To address these questions and other welding dilemmas, special care was taken in Design Guide 21: Welded Connections (Second Edition) to expand upon Special Welding Applications. Enhanced since the First Edition, the Design Guide now includes a chapter on Problems and Fixes which addresses commonly encountered problems with practical advice to solve the issues.

In the August 2019 SE University session, Duane Miller, PE, from The Lincoln Electric Company, presented Introducing Design Guide 21: Welded Connections (Second Edition). Duane covered some unique requirements for special welding applications, suggested potential solutions to frequently encountered problems associated with welded construction, and reviewed the approach used in AWS D1.1 to address unusual situations and the role of the EOR.

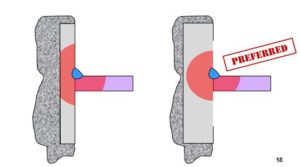

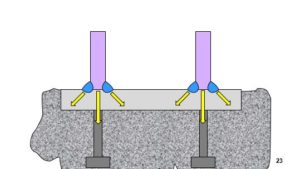

Duane began by offering 10 tips to avoid pitfalls with welding on in-place embed plates as covered in Chapter 14.14 of Design Guide 21. Welding to in-place plates can cause cracking of the surrounding concrete due to expansion or distortion of the heated steel.

The following tips can minimize the heat effects from welding:

1. Use embed plates that are ½” [13mm] thick.

2. Select steel grades and thicknesses for which preheat of the embeds will not be required.

3. Arrange anchorage elements away from the locations where field welds will be required.

4. Design embed plate assemblies to resist distortion.

5. Design the field welded connection to allow for the smallest weld size possible.

6. Provide a perimeter gap between the edge of the embed and the concrete.

7. Allow the concrete to dry and cure before field welding.

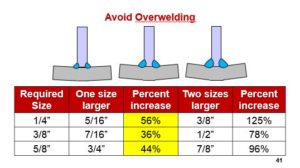

8. Avoid overwelding in the field.

9. Control interpass temperature.

10. Test critical assemblies with mock ups.

Additional consideration should be taken when welding to stainless steel embed plates, as stainless steel distorts significantly more than carbon steel, thus making these tips more critical to the success of welding to stainless steel embeds. Welding to galvanized steel is addressed in Chapter 14.2 and the concepts covered there would apply to galvanized embed plates as well. Using these tips will minimize many of the issues that can arise when welding to in-place embed plates.

In September 2019, SE University welcomed James O. Malley, SE, from Degenkolb Engineers, to present Changes to the Seismic Design of Steel Structures. Jim designated the Earthquake Engineering Research Institute (EERI) Learning from Earthquakes (LFE) Endowment Campaign Fund (http://www.learningfromearthquakes.org/) for the SEU Speaker Inspires donation of the month.

Jim shared: “I selected this fund because EERI’s LFE program made a very significant impact on my career and those of many others by providing earthquake professionals from all disciplines with the opportunity to work together at the site of major earthquakes and share those experiences with the entire earthquake community. The EERI LFE program has made important and lasting contributions to improved understanding of the impacts created by earthquakes and has directly led to many significant advances in seismic design. The LFE endowment fund will guarantee that these contributions will continue for decades to come.”

To learn more about this endowment fund visit http://www.learningfromearthquakes.org/images/EERI-LFE-Endowment-Case-Statement-V10.pdf.

Thank you, Jim, for helping structural engineers with your SE University session, and for your designation of the Earthquake Engineering Research Institute (EERI) Learning from Earthquakes (LFE) Endowment Campaign Fund as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

In August 2019, Duane Miller, PE, from the Lincoln Electric Company, presented Introducing Design Guide 21: Welded Connections (Second Edition). Duane previously nominated The City Mission in Cleveland (https://www.thecitymission.org) for the SEU Speaker Inspires donation of the month when he spoke for SE University in 2017, and he has chosen to do the same in 2019.

Duane shared why he chose The City Mission: “An icon in the welding world, Mr. Omer W. Blodgett passed away in January 2017 at the age of 99. In his honor, his family has requested donations be made to the Cleveland City Mission, an organization that has for over a century provided help and hope to Cleveland’s hurting and homeless; in his honor, I’d like this SEU donation to be made. Mr. Blodgett’s was a longtime supporter of not only the Cleveland City Mission, but of similar organizations in other major cities throughout the US. To me, Mr. Blodgett was my mentor. In an unselfish way, he wanted me to “take over his work” and he showed me how to do so. I’ll never replace him—no one will—but he taught me how to continue to do what he did. He was an exceptional engineer, a tremendous teacher and an consistent Christian, leaving a legacy and an example for all of us to model.”

Thank you, Duane, for helping structural engineers with your SE University session, and for your designation of The City Mission in Cleveland as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

In June 2019, SE University welcomed Lori Koch, PE, from American Wood Council, to present 2018 National Design Specification (NDS) Changes. Lori designated the Richmond SPCA (https://richmondspca.org/) for the SEU Speaker Inspires donation of the month.

Lori shared that she chose this organization because: “They are a great local no kill shelter here in Richmond where I live and they provided me with my slightly chubby but very fluffy and cute boy, French Fry, as seen in this photo.”

Thank you, Lori, for helping structural engineers with your SE University session, and for your designation of the the Richmond SPCA as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

In April 2019, SE University welcomed Cathleen Jacinto, PE, SE, from FORSE Consulting to present Lintels for Masonry Walls. Cathleen designated the Children’s Hospital of Orange County (https://www.choc.org/) for the SEU Speaker Inspires donation of the month.

Cathleen shared that she chose this organization because: “Children’s Hospital of Orange County is an amazing organization that has changed the lives of many children and families experiencing their hardest of times. Their brilliant staff and positive environment bring about miracles everyday, for which I am very grateful.”

Thank you, Cathleen, for helping structural engineers with your SE University session, and for your designation of the the Children’s Hospital of Orange County as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

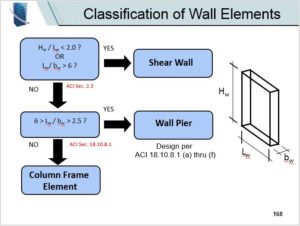

When does a shear wall turn into a wall pier? Have you struggled in the past to decide whether the short wall segments that surround a loading dock opening qualify as a wall pier or a column frame element in your tilt-up wall design? Each type of wall element demands different detailing requirements, and more than one element can be found in the same wall panel.

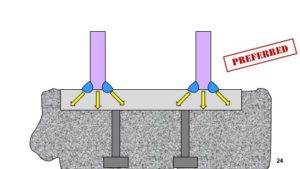

In the July 2019 SE University session, John Lawson, PE, SE, from Cal Poly – San Luis Obispo, presented Engineering Tilt-Up: Design Provisions Born from Past Experience. John reviewed how past failures have influenced current design practices and explained the implementation of current slender wall provisions and how to classify wall elements. He also covered wall anchorage forces and how they get transferred into the diaphragm and potential issues with both steel and wood deck roofs.

John helped clarify how to classify wall elements in tilt-up wall construction. Using the following flow chart, walls can be classified based on their length and thickness.

Once the wall has been classified as a shear wall, wall pier or column frame, the element can then be designed based on the applicable provision in ACI. Wall pier elements are a recent addition to ACI 318, beginning in 2011, and are now referenced in ACI 318-14 in section 18.10.8. Using the correct wall classification will ensure your tilt-up designs meet the detailing requirements in the code and perform in the way you intend for lateral resistance.

26 Jul 2019

2018 National Design Specification Changes

Have you reviewed the upcoming changes in the 2018 National Design Specification? Many changes resulted from changes to other reference standards, and it is important to note their impact on future wood design.

In the June 2019 SE University session, Lori Koch, PE, from American Wood Council, presented 2018 National Design Specification (NDS) Changes. Lori outlined and explained the changes included in each chapter and addressed how the wind load increases in ASCE 7-16 affected the NDS provisions.

Among the changes were new provisions for withdrawal design values for Roof Sheathing Ring Shank nails, as well as new design provisions for fastener head pull through values, both in response to the significant increases in Component and Cladding wind pressures in ASCE 7-16. Other significant changes include the addition of a volume factor, Cv, for structural composite lumber and revisions to the Cross Laminated Timber deflections provisions to be consistent with the terminology used in ANSI/APA PRG 320-2017.

In case you missed Lori’s presentation, or if you want to print a quick reference of the changes to the 2018 NDS, click here to access the AWC’s publication highlighting all relevant additions or alterations. At the end of the article, AWC has provided an Appendix: Summary of Changes, which details all the changes by chapter.

26 Jul 2019

Box Beam Design in Cold-formed Steel

Have you struggled to find a good reference for the design of built-up members in cold-formed steel? The code tends to address some assemblies used in a few applications, but often leaves the engineer to determine how design equations may need to be modified for dissimilar shapes or configurations.

In the May 2019 SE University session, Roger LaBoube, PhD, PE, from Missouri University of Science and Technology, presented Built-Up Member Design (Cold-Formed Steel). During the session, Roger reviewed the applicable cold-formed steel standards for framing members vs. other cold-formed applications, discussed economical solutions for stud packs, and walked through a design example of a built-up box beam that is not specifically enabled by the current design standards.

Perhaps the most anticipated topic in the session included Roger’s rationale for using AISI S100 as it can apply to a built-up box beam section. To hear Roger’s explanation and his discussion regarding the changes needed to use the applicable equations in D1.1, click on the video below:

For further clarification, the CFSEI Tech Note TN G104-14 – Welded Box-Beam Flexure Design can be purchased from the link, or it is available as a free download to CFSEI members.