26 May / 2020

Increasing Deck Diaphragm Shear Capacities

When designing large roof deck diaphragms, the shear requirements at the perimeter often far exceed those in the field, so much so that the more commonly used lighter gage decks and typical attachment designs can be inadequate. What is the best way to increase the deck diaphragm shear strength while also minimizing any cost increases?

In June 2018, Keith Cullum, PE, from Simpson Strong-Tie gave a presentation on Steel Deck Diaphragm Attachment. Keith reviewed the function and components of a steel deck diaphragm and compared common attachment methods. He also talked about appropriate standards and building code references and frequent challenges associated with designing steel deck diaphragms. At the end of the session, a question was asked about the best approach to increasing the deck diaphragm shear capacity in the most cost-effective manner. Watch this short video to hear Keith explain his step-wise strategy to increasing shear capacities.

To learn more about steel deck attachment and access additional design resources, please review our other blog post about Steel Deck Diaphragm Calculators and Resources from Keith Cullum’s SE University session.

26 Apr / 2020

SE Solutions Matching Contributions to Feeding America

SE Solutions would like to do our part to help others in need given this extremely difficult time for many people across the country. In response to the many Americans facing unemployment and economic hardship as a result of the coronavirus outbreak, SE Solutions would like to assist others in need through Feeding America.

SE Solutions would like to do our part to help others in need given this extremely difficult time for many people across the country. In response to the many Americans facing unemployment and economic hardship as a result of the coronavirus outbreak, SE Solutions would like to assist others in need through Feeding America.

The Feeding America network is the nation’s largest domestic hunger-relief organization. Feeding America is working hard to meet the increased demand on local food banks throughout the country.

Therefore, for anyone willing to make any donation to Feeding America (https://www.feedingamerica.

Thank you for being part of our SE Solutions community and we hope everyone is staying safe and healthy.

23 Apr / 2020

Practical Aspects of Steel Fiber Reinforced Concrete

Steel fiber reinforced concrete (SFRC) is still somewhat new to many structural engineers, but its uses are gaining in popularity, and structural engineers should become more familiar with its use, design, and practical applications. Clients are always looking for new, innovative, and cost effective solutions, and SFRC may be the answer on your next project.

In the February 2020 SE University session, Claire Gandee, from Bekaert, presented Steel Fiber Reinforced Concrete. Claire reviewed the basics of steel fiber reinforced concrete (SFRC) and covered the applicable code references for the design of SFRC. She also covered the design approaches typically used for SFRC and made practical recommendations for specifying and for the placement/finishing of SFRC. Claire explained the benefits of using SFRC including possible economic savings.

Claire reviewed many of the practical aspects of placing and finishing when using SFRC. To hear Claire cover many of her frequently asked questions about SFRC, watch this short 4 minute video:

In March 2020, SE University welcomed Matthew Rechtien, PE, Esq., from Walter P. Moore, to present 2020 Engineering Ethics Update. Matt designated Friends of Perryville Battlefield (https://www.friendsofperryville.org) for our SEU Speaker Inspires donation for the month.

Matt shared, “On October 8, 1862, nearly 8,000 Americans fell in the drought-parched Chaplin Hills of Kentucky during the Battle of Perryville. Perryville played a pivotal role in our nation’s most impactful event. Although the clash is oft-forgotten, those Americans should be remembered and that sacred ground, one of the most pristine civil war battlefields remaining, should be protected. The Friends of Perryville Battlefield is committed to both missions, which I am humbled to advance.”

Thank you, Matt, for helping structural engineers with your SE University session, and for your designation of Friends of Perryville Battlefield as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

23 Apr / 2020

Specifying Steel Fiber Reinforced Concrete

Steel fiber reinforced concrete (SFRC) is gaining in popularity, especially in designs for industrial slabs on grade. Steel fibers can add strength and increase fatigue resistance, impact resistance, and crack control which make it ideal for large scale slabs where the use of welded wire fabric can be eliminated. The addition of steel fibers may be an economical option, but if you’ve never used them, you might wonder what is the best method to properly specify SFRC?

In the February 2020 SE University session, Claire Gandee, from Bekaert, presented Steel Fiber Reinforced Concrete. Claire reviewed the basics of SFRC and covered the applicable code references for design. She also covered the design approaches typically used for SFRC and made practical recommendations for specifying and for the placement/finishing of SFRC. Claire explained the benefits of using SFRC, including possible economic savings.

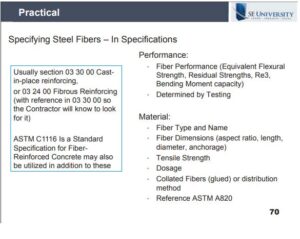

Claire shared the critical information that should be included when specifying SFRC. However, it is most important to be sure the contractor and others on the project can readily find the information, and this is best achieved by including it in the specs within the 03 33 00 Cast In Place Reinforcing or alternately within the 03 24 00 Fibrous Reinforcing, including a reference in the 03 33 00 section to be sure it is not missed by the contractor. ASTM C1116 is a standard specification for Fiber Reinforced Concrete which can be referenced in supplement to performance and material properties of the steel fibers utilized in a project.

Within the specs, the following performance and material requirements should be delineated:

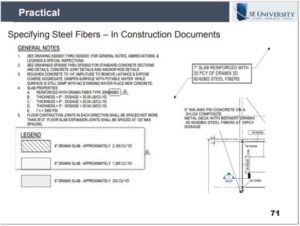

Claire also provided typical drawing notes that give examples of specifying SFRC on construction documents:

These examples provide a good basis to get started using SFRC on projects where performance improvements help the end-user, and/or when it can save time and money for clients. While steel fiber reinforcing may be new to some, open communication with the contractor and manufacturer can eliminate any mishaps when using SFRC on your first project.

31 Mar / 2020

Tips on Working from a Home Based Office

In February 2020, SE University welcomed Claire Gandee, from Bekaert, to present Steel Fiber Reinforced Concrete. Claire designated The Dharma Project (https://www.thedharmaproject.org/) for our SEU Speaker Inspires donation for the month.

Claire shared, “This group brings yoga, meditation and mindfulness to folks who might otherwise have no access to these valuable practices, such as police officers, incarcerated youth, and inner-city school students. I believe in the value and benefits of this work and hope that more people can experience the important work the Dharma Project offers.”

Thank you, Claire, for helping structural engineers with your SE University session, and for your designation of The Dharma Project as one of our SEU Speaker Inspires Organizations of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

SE University / SE Solutions is pleased to support Project C.U.R.E. and their efforts in collecting and donating all of their available medical supplies to combat the Covid-19 crisis throughout America and globally.

SE University / SE Solutions is pleased to support Project C.U.R.E. and their efforts in collecting and donating all of their available medical supplies to combat the Covid-19 crisis throughout America and globally.

Project C.U.R.E. identifies, solicits, collects, sorts and distributes medical supplies and services according to the imperative needs of the world. In response to COVID-19, Project C.U.R.E. is making their resources available to hospitals and first responders throughout the United States. They are donating all of their masks, gloves, PPE’s and other items needed to fight COVID-19 to these heroes. One hundred percent of the items that individuals and companies give to the local fight against COVID-19 will be given to the brave men and women on the front lines of this fight in our communities here in the U.S..

Learn more about Project C.U.R.E at www.projectcure.org or donate to support their relief efforts here.

28 Feb / 2020

Problem Solved: Out-of-Tolerance Fillet Weld Joints

Have you encountered fit-up problems in the field for fillet welded connections? What has been your solution? AWS D1.1 requires that the engineer approve any alternative acceptance criteria for production welds, but the Code only provides general stipulations applicable to most situations. Finding an acceptable alternative for fit-up issues often plagues engineers, however in the Second Edition of Design Guide 21: Welded Connections, Chapter 15.4.2 offers solutions for out-of-tolerance weld joints.

In the August 2019 SE University session, Duane Miller, PE, from The Lincoln Electric Company, presented Introducing Design Guide 21: Welded Connections (Second Edition). Duane covered some unique requirements for special welding applications, suggested potential solutions to frequently encountered problems associated with welded construction, and reviewed the approach used in AWS D1.1 to address unusual situations and the role of the EOR.

Duane addressed how out of tolerance fillet weld joints might be handled according to Design Guide 21. Watch this short 4 minute video to hear Duane discuss buttering and changing the fillet weld to a CJP groove weld as two solutions for out-of-tolerance fillet weld joints.

In January 2020, SE University welcomed Doug Allen, PE, from Simpson StrongTie, to present Delegated Design: Addressing Potential Risks with Proper Project Management. Doug designated Team Rubicon (https://teamrubiconusa.org/) for our SEU Speaker Inspires donation for the month.

Doug shared, “I’d like to donate to Team Rubicon as they are a great organization that supports veterans responding to natural disasters. Simpson Strong-Tie has witnessed Team Rubicon making a difference following natural disasters, most recently Hurricane Dorian in the Bahamas.”

Team Rubicon’s mission is providing disaster relief to those affected by natural disasters, be they domestic or international. By pairing the skills and experiences of military veterans with first responders, medical professionals, and technology solutions, Team Rubicon aims to provide the greatest service and impact possible.

Thank you, Doug, for helping structural engineers with your SE University session, and for your designation of Team Rubicon as one of our SEU Speaker Inspires Organizations of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.