25 Nov 2024

Happy Thanksgiving from SE Solutions!

As we enter this Thanksgiving week, we would like to take this opportunity to thank our SE Solutions community and wish everyone a joyous holiday. SE Solutions and SEU are thankful to our clients and speakers who have made it possible for us to contribute to many charitable organizations during the past year through our SEU Speaker Inspires program and to support hurricane recovery efforts in 2024.

In June 2024, SEU welcomed Josh Canova, PE, from New Millenium, and Gerald McKenzie, PE, from Vulcraft, to present Concentrated and Non-Uniform Loading on Steel Deck. Josh and Gerald have designated One More Child (https://onemorechild.org/) for our SEU Speaker Inspires donation for the month.

Josh shared, “As a husband and father who is not only blessed with a family but blessed to be able to provide for my family, I wanted to choose an organization that supports and cares for those who have had a tougher go at things and find themselves in difficult situations. One More Child is a faith-based organization that serves the most vulnerable in our society by supporting children in need, combatting human trafficking, and providing support for single moms or families in need.”

Thank you, Josh and Gerald, for helping structural engineers with your SEU session, and for your designation of One More Child as our SEU Speaker Inspires Organization of the Month!

SEU began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SEU to make a donation to help improve our world.

In May 2024, SEU welcomed Matt Timmers, SE, from John A. Martin & Associates, to present Mass Timber Structural Design. Matt has designated Surfrider Foundation (surfrider.org) for our SEU Speaker Inspires donation for the month.

Matt shared, “The Surfrider Foundation is best known for their advocacy for ocean health, a cause near and dear to my heart and central to global climate change issues. Their mission includes commitment to broad global sustainability goals, including the reduction of plastic waste, ensuring equitable access to coastline, and protecting the health of both coastal and inland water systems. For all these reasons I support their mission and chose them as my SEU Speaker Inspire organization.”

Thank you, Matt, for helping structural engineers with your SEU session, and for your designation of Surfrider Foundation as our SEU Speaker Inspires Organization of the Month!

SEU began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SEU to make a donation to help improve our world.

Masonry wall openings are a common location for diagonal cracks which can result from improperly detailed lintels. Steel lintels can be properly detailed to span openings in masonry walls, but would a masonry lintel be more efficient?

In the September 2024 SEU session, Scott Walkowicz, PE, from Walkowicz Consulting Engineers, presented Masonry Design and Detailing: Using Your Owner’s Money Wisely. Scott discussed the structural performance benefits and building improvements achieved through the use of masonry, as both a structure and an outer envelope. He identified ways to reduce cost and minimize material waste in masonry design and detailing. He also examined masonry details to create functional, durable, and constructable masonry assemblies.

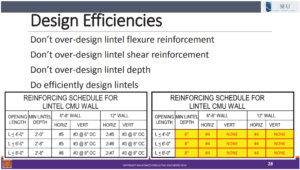

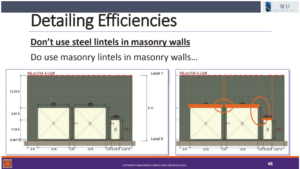

Scott recommends using masonry lintels in masonry walls, as opposed to steel lintels. Steel lintels can cause many issues in masonry walls and are rarely needed. Differential movement is among the most problematic issues when using steel lintels in masonry walls. Also, in the event the steel lintel is accidentally or erroneously restrained, very large forces can develop in the steel and cause significant cracking in the masonry wall. Masonry lintels provide a more cohesive design and can be designed to resist significant forces. As you can see below, an efficient masonry lintel design requires minimal reinforcement to span short distances. When necessary, reinforcement can be added to increase the capacity of masonry lintels carrying significant forces. However, engineers should consider their typical lintel schedules to be sure efficient reinforcing is specified to minimize the overall project cost.

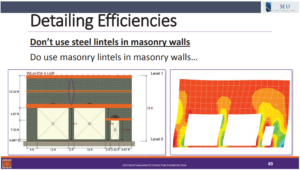

Masonry lintels also contribute to stronger walls. As you can see below, several control joints are necessary in the wall using steel lintels. These joints reduce the capacity of the wall, increase the chance of differential movement between the lintel and the wall, and increase the chance of cracks in the masonry. Replacing the steel lintels with masonry bond beams and lintels create strong wall action, as shown in the finite element model on the slide below. This wall is more efficient and results in a better product.

As a best practice, engineers should eliminate steel lintel schedules as typical details on their masonry projects and replace them with an efficient typical masonry lintel schedule. When required for heavy loads, additional masonry lintel details are capable of carrying significant loads and should be designed for specific loading conditions. Efficient masonry lintels used throughout a masonry project will reduce the overall cost for the owner and minimize problems typically created by steel lintels.

The cost of masonry construction can vary widely, in part due to inefficient designs which can drive up the labor costs on a structural project. There are many strategies which can reduce unnecessary costs in masonry construction, but are you aware of common inefficiencies engineers specify which are responsible for some of these added costs?

In the September 2024 SEU session, Scott Walkowicz, PE, from Walkowicz Consulting Engineers, presented Masonry Design and Detailing: Using Your Owner’s Money Wisely. Scott discussed the structural performance benefits and building improvements achieved through the use of masonry, as both a structure and an outer envelope. He identified ways to reduce cost and minimize material waste in masonry design and detailing. He also examined masonry details to create functional, durable, and constructable masonry assemblies.

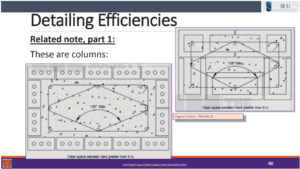

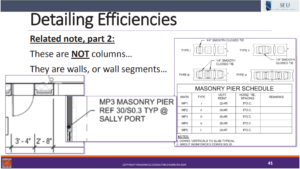

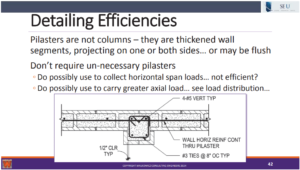

Scott covered a number of useful tips to reduce the cost of masonry construction. One common inefficiency which drives up the cost of masonry construction is the unnecessary use of confinement ties in masonry walls or pilasters. Scott noted that confinement ties are only required by code in masonry columns and wall segments in which the primary steel is required to resist compressive loads. Many times typical masonry details are shown to include confinement ties in wall segments (commonly called piers) and pilasters when engineers assume that piers and pilasters are columns within a wall. However, pilasters are considered thickened walls and not columns and wall segments are simply wall segments. Thus, confining ties would only be required when the primary reinforcement is analytically needed to resist compression forces. As you can see in the slides below, Scott notes common details for what would and would not qualify as columns in masonry construction.

Confinement ties do add to the material costs of a project, but especially drive up the labor costs due to the extra time spent placing and tying off this additional reinforcement. In most cases, confinement ties are not needed in walls or pilasters, unless the engineers has included them in their analysis to resist axial loads. Engineers should often review their typical masonry details to be sure they are practical and efficient, and meet code requirements. Typical details which include unnecessary reinforcement should be revised to reduce project costs.

In April 2024, SEU welcomed Matthew Rechtien, PE, Esq., from Walter P. Moore, to present 2024 Engineering Ethics Update: Engineers’ Duty to Report. In prior years, Matt has designated Friends of Perryville Battlefield (https://www.friendsofperryville.org) for our SEU Speaker Inspires donation for the month and he has chosen to do the same in 2024.

Matt shared, “On October 8, 1862, nearly 8,000 Americans fell in the drought-parched Chaplin Hills of Kentucky during the Battle of Perryville. Perryville played a pivotal role in our nation’s most impactful event. Although the clash is oft-forgotten, those Americans should be remembered and that sacred ground, one of the most pristine civil war battlefields remaining, should be protected. The Friends of Perryville Battlefield is committed to both missions, which I am humbled to advance.”

Thank you, Matt, for helping structural engineers with your SEU session, and for your designation of Friends of Perryville Battlefield as our SEU Speaker Inspires Organization of the Month!

SEU began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SEU to make a donation to help improve our world.

Are you considering thermal effects in the steel structures you design? A building which is exposed to the elements might be an obvious example of a structure that will experience thermal changes, but are there other structures that should be investigated for possible thermal self-straining forces? How do engineers predict these forces and what does the building code require to prevent harmful effects from temperature changes?

In the July 2024 SEU Session, Barry Arnold, PE, SE, retired VP from ARW Engineers, presented Temperature Effects in Steel Structures. Barry identified code requirements for thermal forces and applicable equations and explained some common errors in the application of thermal forces. Barry also pointed out some possible consequences of ignoring thermal forces in steel structures, and showed where and how thermal forces manifest themselves.

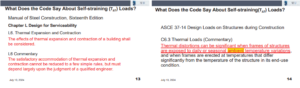

ASCE addresses thermal, or self-straining, forces in Section 2.3.4 and states that “Where the structural effects of T [ΔT] are expected to adversely affect structural safety or performance T [ΔT] shall be considered in combinations with other loads…” ASCE further addresses thermal forces in the Commentary in Section C6.3 and notes that structures will experience thermal distortions which are significant when exposed to “ambient temperature variations,” thus, engineers will need to define this variation on their structure. Barry suggested the use of the word “ambient” may lead to a common error in determining the possible thermal changes during the life of the structure, To hear Barry explain how complicated this issue can be, watch this short video:

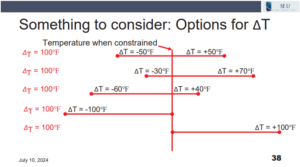

While there are many factors to consider when determining ΔT, Barry showed his method for approximating ΔT. As you can see in the following slide, Barry uses a ΔT of 100 degrees while considering the temperature of the steel when constrained and the geographic location and building type.

This method offers a good starting point, however, as AISC’s Manual of Steel Construction notes in L6 of the commentary, “The satisfactory accommodation of thermal expansion and contraction cannot be reduced to a few simple rules, but must depend largely upon the judgment of a qualified engineer.” Thermal forces can cause a variety of issues in steel structures, and a qualified engineer should consider the many variables which can affect these forces within the structure.

In March 2024, D. Matthew Stuart, PE, SE, PEng., F.ASCE, F.SEI, A.NAFE, from Partner Engineering and Science, Inc., presented Building Envelope Deterioration Investigation and Repair – Parts 1 and 2. Previously in 2023, Matthew nominated the United Methodist Committee on Relief (UMCOR) (UMCOR – Global Ministries (umcmission.org)) for the SEU Speaker Inspires donation of the month, and he has chosen to do the same in 2024.

According to it’s mission statement, UMCOR is the humanitarian relief and development arm of The United Methodist Church and it assists churches to become involved globally in direct ministry to persons in need. UMCOR comes alongside those who suffer from natural or human-caused disasters – famine, hurricane, war, flood, fire or other events—to alleviate suffering and serve as a source of help and hope for the vulnerable. UMCOR provides relief, response and long-term recovery grants when events overwhelm a community’s ability to recover on their own. UMCOR also provides technical support and training for partners to address emerging and ongoing issues related to disaster relief, recovery, and long-term health and development.

Thank you, Matthew, for helping structural engineers with your SE University session, and for your designation of the United Methodist Committee on Relief as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

24 Aug 2024

Scissor Lift Wheel Loads: Can they be Combined?

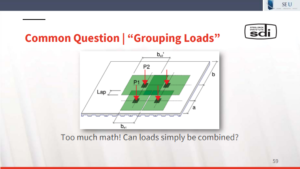

Engineers are regularly faced with the dilemma of spending the extra time it takes to do complex hand calculations for a moving scissor lift to answer the contractor’s question: How much weight can the scissor lift carry? Can I save some time and just combine these wheel loads? Or can I simplify the calculations and combine the wheel loads to determine the maximum allowable point load on the deck?

In the June 2024 SEU Session, Joshua Canova, PE, from New Millenium, and Gerald McKenzie, PE, SE, from Vulcraft, on behalf of the Steel Deck Institute, presented Concentrated and Non-Uniform Loading on Steel Deck. Josh and Gerald explained the procedure for developing “simple” load diagrams based on recognized load distribution and explained deck limit states under concentrated loads. They also identified current and expanded SDI design approaches for concentrated loads.

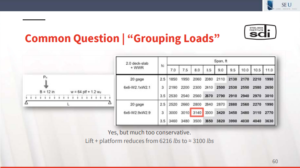

After walking the audience through the detailed calculations establishing the capacity of steel deck to support a moving scissor lift load, Josh addressed the most common question posed by structural engineers looking to save time and money, ”Can scissor lift wheel loads be grouped into one load?” Josh examined the results from combining these wheel loads and used the SDI Floor Deck Design Manual’s tables for Maximum Nominal Scissor Lift Wheel Loads to address this question. As expected, grouping the wheel loads compared to addressing them individually would yield a conservative solution. But how big of a tradeoff does this short cut yield? As you can see in the slide below, the capacity of the example floor deck, considering individual wheel loads, will yield an allowable scissor lift load of 6216 pounds. However, combining the loads into one results in an allowable scissor lift load of 3100 pounds. This effectively reduces the allowed scissor lift load by more than half. While this short cut may save calculation time, it may add to increases in construction time and labor due to the reduced load allowed on the scissor lift.

While the hand calculations may be cumbersome, SDI provides useful tables within the Floor Deck Design Manual, Second Edition for common steel deck configurations which can be used to determine the Maximum Nominal Scissor Lift Wheel Load. These tables have been developed by moving a scissor lift one inch at a time across the length of a given deck configuration, turned 90 degrees and then moved back one inch at a time and determining the maximum capacity of the deck limit states. The tables are based on conservative conditions and assumptions to provide the lower bounds that any SDI member company should be able to meet; they are not necessarily accurate when it comes to maximum possible capacities for a specific manufacturer but provide accurate capacities based on the given assumptions and confidence in what any SDI member company could supply. To purchase a copy of the FDDM2 as well as other technical guides related to steel deck design, visit the Steel Deck Institute (sdi.org). Engineers are able to use these tables to both reduce their calculation time and provide a more accurate estimate of the capacity of the steel deck to resist the scissor lift wheel loads.

29 Jul 2024

Mass Timber Connection Fire Protection

Fire protection for mass timber structures has become less ambiguous for engineers since the 2021 publication of American Wood Council’s NDS Technical Report 10 Calculating the Fire Resistance of Wood Members and Assemblies. Are you familiar with the allowances and requirements for fire resistance protection of wood connections in mass timber structures?

In the May 2024 SEU session, Matt Timmers, SE, from John A. Martin & Associates, Inc., presented Mass Timber Structural Design. Matt reviewed the International Building Code requirements for mass timber including fire resistance and building type. He identified gravity and lateral framing components of mass timber buildings, including typical assemblies. He also defined the requirements for fire design of structural members and connections.

Matt reviewed the fire protection guidelines laid out by the IBC, NDS and NDS TR10 which dictates, “The fire-resistance rating of the mass timber elements shall consist of the fire resistance of the unprotected element added to the protection time of the non-combustible protection.” Similarly, according to NDS Section 16.3, “Wood connections, including connectors, fasteners, and portions of wood members included in the connection design, shall be protected from fire exposure for the required fire resistance time.” So, how does an engineer accomplish this task of protecting wood connections from fire?

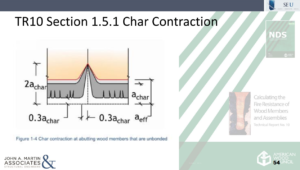

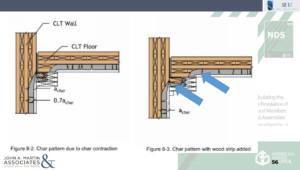

Matt gave several examples of ways to protect wood connectors so that the char pattern due to char contraction will not penetrate to the connectors. NDS TR10 specifies that “Char contraction at unbonded wood member ends and edges results in ignition of wood surfaces in the gaps at these locations. The penetration of ignition into these gaps is assumed to be twice the char depth, 2achar.” This is illustrated in the slide below.

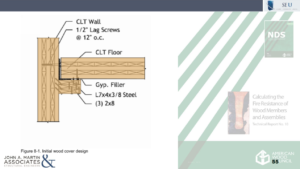

Thus, all wood connections need to be protected from the char depth prescribed at unbonded wood member ends. For example, Matt presented an example of a CLT floor beam connection to a CLT wall, as shown below. In order to provide fire protection to the metal ledger angle, the engineer has specified (3) 2×8 wood blocks to be provided.

However, the char pattern for this assembly as seen in Figure 8-2 shows that the fire will breach the provided protection on the back side of the angle attachment and at the tip of the angle. Additional wood blocking should be provided, as shown in Figure 8-3. Here, the (3) 2x10s prevent the char from reaching the angle leg, and an additional 1×1 wood strip protects the back side of the angle from char penetration.

Matt noted the additional wood blocking can become unsightly for architects or specifying professionals who may not be expecting the additional fire protection at the connections. Proprietary hidden connections are available from several manufacturers which may be a more acceptable alternative in areas of the structure that are exposed to view. Communication early in the design process is essential to ensure the mass timber structure maintains aesthetic goals while still maintaining the code-required fire protection.

Additional examples and information about char depths and wood connection assemblies can be found in the NDS Technical Report 10 Calculating the Fire Resistance of Wood Members and Assemblies. This document is FREE to download through this link and provides the results of many research studies into calculating the fire resistance of wood connection assemblies.