26 Aug / 2021

Principles for Concise Technical Writing

When was the last time you reflected on your writing process for emails, reports, or client updates? Have you considered ways to improve how your audience may perceive your document? Writing is truly an artform, and technical writing requires great skill to engage and inform readers without being unnecessarily complex and difficult for readers to understand. Producing clear and concise documents can help communicate technical information effectively and improve your esteem with your readers or clients.

In October 2018, Janel Miller, from the University of Wisconsin at Madison, gave a presentation on Improving Clarity, Coherence, and Conciseness in Technical Writing. Janel reviewed how to prepare coherent documents, engage and persuade readers, and apply principles of concise writing to improve clarity.

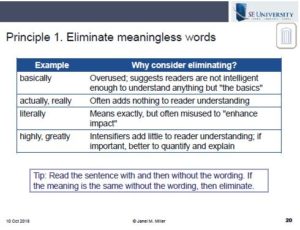

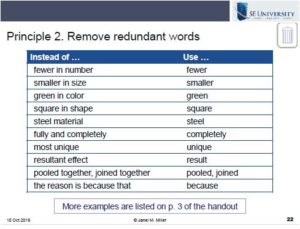

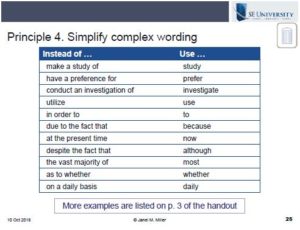

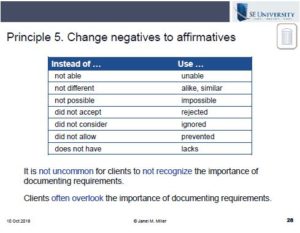

Janel gave excellent pointers on how to simplify writing to reduce the verbal complexity so readers can understand the technical complexity. She reviewed Joseph Williams’ five principles of concise writing from the text Style: Toward Clarity and Grace. These principles are

- Eliminate meaningless words

- Remove redundant words

- Delete what readers can infer

- Simplify complicated wording

- Change negative to affirmatives

After drafting the basic concepts of your document, take some time to edit using these basic principles to reduce wordiness and improve clarity. Most readers will appreciate a more concise version of your document which will improve your credibility with those readers.

Janel also provided helpful examples of these principles and ways to apply them in technical writing. Click on the following slides to print your copy for quick reference when preparing your own technical writings.

22 Aug / 2021

Structural Fire Protection

Are you familiar with the significant changes and common failure modes that occur in a steel framed structure during a fire? For over a century, engineers have been using a prescriptive approach to protect steel structures and their occupants from a fire event. The International Building Code also permits the application of performance-based structural fire design to evaluate structural systems during a fire in a similar manner as other design loads are treated. Could any of your projects benefit from a structural fire engineering design rather than the typical prescribed fire protection?

In the June 2021 SE University session, Erica Fischer, PhD, PE, from Oregon State University, presented Structural Fire Protection. Erica explained the difference between a prescriptive fire protection design and structural fire engineering. Erica qualitatively showed how steel strength and stiffness change with increasing temperature and how boundary conditions for beams and columns can change during a fire event. She also presented a case study showing the benefits of employing fire engineering on a steel framed structure.

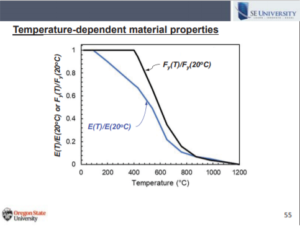

Structural fire engineering becomes a complex endeavor because of the temperature-dependent material properties and the potentially changing boundary conditions throughout a fire. As you might expect, as the temperature increases, both the yield stress and ultimate stress are decreasing and the elastic modulus is decreasing, however they are not decreasing uniformly. Erica included the following slide which shows the complexity of these changing mechanical material properties. As you can see, the yield stress remains constant until about 400 degrees, but the stiffness decreases at a much lower temperature and they are not decreasing linearly.

Additionally, not all steel components have the same degradation patterns of material properties. Steel bolts, for example, respond differently than mild steel to thermal increases. Thus, predicting the behavior of connections can be very complex and the controlling failure modes at elevated temperatures will be different than those at ambient temperature. To hear Erica explain the changes to boundary conditions throughout a fire, watch this short 3 minute video:

During her presentation, Erica suggested engineers refer to ASCE’s Structural Fire Engineering MOP 138 book to learn more about performance-based structural fire engineering. This book is available on ASCE’s website for purchase as an e-book or in print. This reference provides guidance on calculated design of a structure to withstand the thermal load effects of fire, including performance objectives and analysis techniques to quantify the structural response to thermal increases.

In June 2021, SE University welcomed Erica Fisher, PhD, PE, from Oregon State University, to present Structural Fire Protection. Erica designated the Girls Build (https://girlsbuild.org/) for our SEU Speaker Inspires donation for the month.

Erica shared “Girls Build provides access and opportunity for young girls to engage with the building construction industry through hands-on learning experiences in the state of Oregon. These types of experiences can change the perception young girls have of the building construction industry and the perception of what careers are possible for them. As engineers, it is critical that we have diversity within our offices so that we can create solutions to societal issues that are applicable to all members of a community.”

Thank you, Erica, for helping structural engineers with your SE University session, and for your designation of Girls Build as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

Effective communication is a skill that is often undervalued in the workplace. We have years of training and multiple degrees to learn our trade, but how much time along the way has been directed at learning to deal effectively with others? Typically, we focus all our energy on learning concrete design techniques (pun intended), but how do we develop our soft skills, in order to promote ourselves and our careers and be productive members of a team? How do we relate to others in an increasingly diverse workplace environment, and learn to thrive with others who may have a different personality type?

In the August 2016 session of SE University, Annie Kao, PE with Simpson Strong-Tie, gave a presentation on Effective Communication Skills for Workplace Conversations and Meetings. One of the main topics that Annie discussed was the benefit of cultivating a reward-state environment as opposed to a threat-state environment in our workplace.

When employees feel they are in a reward-state, they are able to work more effectively, both independently and as part of a team. Annie provided a useful tool to assess which values create a reward-state, and how we can use this information to be more intentional in the way we relate to our coworkers. The online SCARF Assessment looks at five domains that each of us finds more or less valuable depending on our personality – Status, Certainty, Autonomy, Relatedness, and Fairness. After completing the online assessment, the results include a brief description of each domain and how it affects our behavior.

Annie noted that, without knowing what is valued by our peers, we could inadvertently be placing them in a threat-state. For example, managers who really value autonomy may think that they are empowering their team members by giving them the freedom to work without restriction. However, if members of the team value certainty, this level of freedom may place them in a threat-state due to the lack of feedback or guidelines to follow. By understanding our own needs and the needs of others, we can be more cognizant of the way we respond and what type of feedback we give to others. This helps create an atmosphere where everyone feels valued for their contributions.

Annie also provided another resource that helps identify our tendencies toward particular behavior traits. The online DISC Assessment categorizes behavior into four groups – Dominance, Influence, Steadiness, and Conscientiousness. Based on our tendencies toward particular traits, we can be more self-aware of our own strengths and weaknesses, and learn to appreciate the tendencies of others and how their differing personalities can impact the team.

Using these assessment tools in the workplace, we can make intentional changes to our behavior and become more aware of the behavior tendencies of others in order to create a more efficient and enjoyable work environment. Sharing these tools with coworkers can help improve teamwork and elevate our respect for one another.

In May 2021, SE University welcomed Emily Guglielmo, SE, from Martin/Martin Consulting Engineers, to present Serviceability for the Practicing Engineer. Emily designated the SEAONC DEI Endowment Fund (https://www.seaonc.org/page/SEAONCDEI) for our SEU Speaker Inspires donation for the month.

Emily selected the Structural Engineers Association of Northern California (SEAONC) DEI Endowment as it’s a new and innovative way to put words and promises of the past year into action. The Endowment is a funding vehicle that will assure the long-range financial future of a restricted fund to support entities, programs, scholarships and initiatives focused on Diversity/Equity/Inclusion (DEI) in Structural Engineering.

Thank you, Emily, for helping structural engineers with your SE University session, and for your designation of the SEAONC DEI Endowment Fund as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

18 Jun / 2021

Mean Recurrence Intervals for Wind Serviceability

When considering drift limits, how conservative are you when selecting your Mean Recurrence Interval wind load? Do you typically use the nominal wind speeds from the maps provided in ASCE 7 and consider those to be conservative for serviceability? Engineers can use their judgment to best decide which MRI is appropriate for any given project, and in many cases, a less restrictive MRI might be best suited for drift evaluation.

In the May 2021 SE University session, Emily Guglielmo, SE, from Martin/Martin, presented Serviceability for the Practicing Engineer. Emily explained the current serviceability requirements that are codified and addressed key serviceability concerns for various building materials. Emily discussed practical limits for both vertical and horizontal deflections and the need for engineering judgment in serviceability considerations.

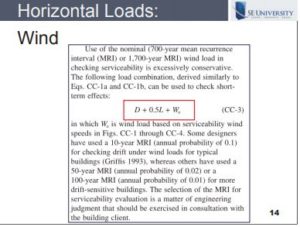

For horizontal loads, Emily specifically addressed drift due to wind since seismic deflections are typically controlled by life safety considerations. Wind, however, is a daily phenomenon for which a building should be properly designed to handle appropriate deflections without resulting damage to the structure or its finishes. Emily noted that in the Commentary to Appendix C in ASCE 7, the mean recurrence interval (MRI) is addressed for use in determining deflections for serviceability, as shown on the slide below.

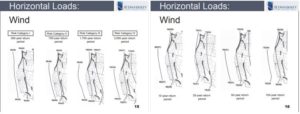

Equation CC-3 introduces a term, Wa, which does not appear in the standard, but is rather specific to the commentary. This Wa term is a wind load based on serviceability wind speeds from Figures CC1-CC4 which include wind speeds for MRIs of 10, 25, 50, and 100-year returns. Emily included comparisons between the wind speed maps from the standard to compare to the maps in the commentary.

As shown in the slides, the maps included in the commentary show significantly lower wind speeds and the commentary explicitly states that the “selection of the MRI for serviceability evaluation is a matter of engineering judgment…” Thus, engineers may use a less conservative MRI for serviceability considerations depending on the needs of the client, the materials in use, and the occupancy of the building, and the commentary implies that this is entirely reasonable. Of course, the designer may still opt to use the full nominal wind speed specified in Chapter 26 of the standard as the most conservative option for drift determination.

For some drift sensitive buildings or buildings with brittle finishes, a more conservative MRI would be sensible, however, the availability of the additional maps in the commentary are especially useful for the engineer who wishes to exercise more precise judgment from project to project.

18 Jun / 2021

Determining Blast Design Pressures

Government facilities often require specialized design for blast loads, but some commercial buildings and municipal structures may also be deemed mission critical and need a blast-resistant design. Are you able to determine the design blast load when given a specified charge weight?

In the March 2021 SE University session, Aldo E. McKay, PE, from Protection Engineering Consultants, presented Blast-Resistant Design of Buildings. Aldo shared references and resources available for blast protection of buildings and reviewed the basics of modeling structural systems and components under blast loads. He also explained the blast loading performance objectives and blast loading requirements for different market sectors.

Aldo ran through a quick example to explain the process for determining the design loads on a building when provided with the charge weight and standoff distance of a building for an engineer that may not have access to any specialized software. This process uses charts initially developed by Kingery and Bulmash from spherical blasts in free air, and have been scaled to represent a hemispherical surface burst. To watch Aldo explain this process, click here.

Aldo mentioned that these curves are available in ASCE 59-11 Blast Protection of Buildings which is available for purchase from ASCE. Using the curves, Aldo was able to establish the design incident pressure and incident impulse to use for the blast design on this project. These incident pressures can then be used to design the roof elements or side wall structural elements. This same process can be used to determine the reflective pressure and reflective impulse. These charts can be especially useful for the engineer who does not have specialized software or just needs a quick estimate for design pressures for blast loading.

18 Jun / 2021

“SEU Speaker Inspires” Organization of the Month: UDistrict Foundation Mentoring Program

In April 2021, SE University welcomed Ashley Cagle, PE, SE, from WoodWorks, to present Structural Engineering of Light Frame Wood Over Concrete Podium Structures. Ashley designated UDistrict Foundation Mentoring Program (https://udistrictpt.com/nonprofit-foundation/foundation-mentoring-info/) for our SEU Speaker Inspires donation for the month.

Ashley shared, “The Foundation’s mission is to ‘help children live healthy, productive lives and dream great dreams.’ Through the mentorship program, students, primarily from Title 1 schools in the greater Spokane area, are matched to the specific interests, background, and passions of volunteer mentors, resulting in long-lasting, rewarding relationships. Over the past year of disruptions, the need for steady, reliable relationships in children’s lives has only been highlighted. I have been a mentor with the UDistrict Foundation for the past year and a half and strongly believe in the value of these types of community-oriented, cross-generational relationships.”

Thank you, Ashley, for helping structural engineers with your SE University session, and for your designation of UDistrict Foundation Mentoring Program as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

In March 2021, SE University welcomed Aldo E. McKay, PE, from Protection Engineering Consultants, to present Blast-Resistant Design of Buildings. Aldo designated No Kid Hungry (www.nokidhungry.org) for our SEU Speaker Inspires donation for the month.

Aldo shared, “The ongoing pandemic has impacted all of us in different ways. One of the most severely and negatively impacted groups are kids in low-income communities. Many of the parents of these kids have lost their jobs and these kids often rely on school meals as their only source of food and nutrition. As a result of school closures, many of these low-income families have been left with no means to feed their kids. With our support, No Kid Hungry is committed to feeding kids in these communities to ensure every kid gets three meals a day. I think this is a great cause and something that all of us in a position to help should consider doing.”

Thank you, Aldo, for helping structural engineers with your SE University session, and for your designation of No Kid Hungry as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

20 May / 2021

SE Solutions Provides Scholarships to 3 MSCE Structures Students from Purdue University (2021)

SE Solutions was pleased to recently present scholarships to three Purdue University Structures students to help defray the cost of their education. Mriganabh Boruah, Sarah Bowlin, and Heyi Feng were the recipients of the awards. This is the ninth year that SE Solutions has offered the scholarships.

SE Solutions was pleased to recently present scholarships to three Purdue University Structures students to help defray the cost of their education. Mriganabh Boruah, Sarah Bowlin, and Heyi Feng were the recipients of the awards. This is the ninth year that SE Solutions has offered the scholarships.

Mriganabh Boruah is from Assam, India. He received his bachelor’s degree from the National Institute of Technology Karnataka, Surathkal in 2018 and will be defending his master’s thesis in spring 2021 with a specialization in structural engineering. He had the opportunity to work as a teaching assistant for CE297-Statics for 2 semesters and has worked in the field of non-linear soil-structure interaction in nuclear power plants. His thesis is focused on reducing the computational time in brittle cracking analysis using Adaptive Multi-Time Step Decomposition. He has a job lined up with a structural engineering firm based out of Tulsa, OK and looks forward to being a part of a challenging industry.

Sarah Bowlin graduated with her bachelors degree in civil engineering from Oklahoma State University in May 2019. She plans on graduating with her masters degree from Purdue University in December 2021. She will be staying at Purdue to pursue a PhD in Civil Engineering. Sarah has had the goal of becoming a structural engineer since she was in high school and had the opportunity to take a variety of pre-engineering classes. At Oklahoma State, she was very involved with the Concrete Canoe Team, which sparked her interest in concrete structures. She enjoys learning about the different behaviors and applications for structural concrete, as well as all the other structural materials. She is currently a graduate research assistant focusing on the behavior of unbonded and bonded post-tensioned concrete bridge girders. After finishing school, she would like to find a challenging and rewarding job at a structural engineering firm.

Heyi Feng received his bachelor’s degree in civil engineering at Portland State University in 2019 and will complete his MSCE study with specialization in structural engineering at Purdue University in August 2021. Heyi has been working as a research assistant. His research focuses on finite element analysis of API 12F tanks, performing failure modes determination and fitness-for service analyses. He is also currently working as an engineering intern at Baker Consulting Group. Heyi is hoping to start his career with a firm that allows him to design innovative structures right after his graduation from Purdue.

SE Solutions would like to congratulate each recipient and wish them future success in their fields of study as structural engineers.