In February 2021, SE University welcomed Matthew Rechtien, PE, Esq., from Walter P. Moore, to present Engineering Ethics Update: The New Model Code. In 2020, Matt designated Friends of Perryville Battlefield (https://www.friendsofperryville.org) for our SEU Speaker Inspires donation for the month and he has chosen to do the same in 2021.

Matt shared, “On October 8, 1862, nearly 8,000 Americans fell in the drought-parched Chaplin Hills of Kentucky during the Battle of Perryville. Perryville played a pivotal role in our nation’s most impactful event. Although the clash is oft-forgotten, those Americans should be remembered and that sacred ground, one of the most pristine civil war battlefields remaining, should be protected. The Friends of Perryville Battlefield is committed to both missions, which I am humbled to advance.”

Thank you, Matt, for helping structural engineers with your SE University session, and for your designation of Friends of Perryville Battlefield as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

22 Feb 2021

Scissor Lift Loads on Deck Slabs

How many times has a contractor called you asking to put heavy equipment on your deck slab? How confident have you been in your analysis of the deck capacity with these unexpected loads, or have you defaulted to denying these requests to save any headaches over the complex load distribution from the moving equipment?

In the December 2020 SE University session, Mike Antici, PE, from Nucor / Steel Deck Institute, presented Steel Deck Design for Concentrated and Non-Uniform Loads. Mike explained how to develop simple load diagrams based on the load distribution. He also explained the limit states for slab design under concentrated loads and reviewed the current and new SDI approaches for concentrated loads.

After explaining the equations used to determine the sinusoidal moments that develop within overlapping influence zones from multiple loads on a deck slab, Mike revealed the new tables contained in the Second Edition of the Floor Deck Design Manual which can now be used to determine the nominal scissor lift wheel loads for various configurations of deck slabs. To hear Mike explain the use of these tables along with the assumptions used in their development, click below for a short video clip from his presentation.

These tables will undoubtedly be very useful for the practicing engineer when the contactor calls to request permission to use scissor lifts on the deck slab. In the past, approximations may have been overly conservative, but with the publication of the second edition of the FDDM, engineers now have the equations they need to determine the available capacity for multiple concentrated loads on their deck slabs. The Steel Deck Institute has the Second Editions of both the Floor Deck Design Manual and the Roof Deck Design Manuals available for purchase at their website and they both include new design examples and newly developed load tables for concentrated and moving loads.

22 Feb 2021

HSS Connection Design: A New Approach

AISC 360-16 has some significant changes in the design of connections to rectangular HSS. Engineers have no doubt noticed the removal of some of the HSS connection design tables, however the limits of applicability included in the design tables became an impetus for AISC to provide a more flexible design process for HSS connections.

In the January 2021 SE University session, Kim Olson, PE, from Nucor and presenting on behalf of the Steel Tube Institute, presented Navigating AISC 360-16 HSS Connection Design. Kim identified how the prescriptive nature of Chapter K has been changed to more closely match the rest of the Specification. She also explained the reasoning behind the changes to the limits of applicability and variables in Chapter K and showed how the equations for connecting to the web of a wide flange member from Chapter J can be used to derive similar equations for connecting to rectangular HSS.

The most visible change in AISC 360-16 is the movement away from the prescriptive tables in AISC 360-10 for connecting to rectangular HSS. Although the tables were quick and useful, they were limited in scope and unique in style to the rest of the specification. The new design procedure is specified in Section K2.3 of AISC 360-16 which states that “The available strength of connections to rectangular HSS with concentrated loads shall be determined based on the applicable limit states from Chapter J.”

Referring to Chapter J for this procedure allows the engineer the ability to determine the strength of their exact connection without being limited to the prescribed limits previously included in the specification. More limit states must be checked to determine which controls which is in line with a typical steel connection design.

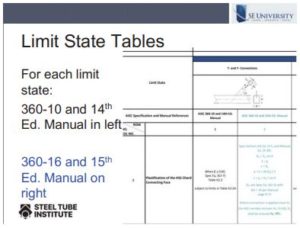

In order to more smoothly transfer from the prescriptive tables to the equations for HSS, Kim shared that the Steel Tube Institute has provided Limit State Tables on their website which highlight what was provided previously in AISC 360-10 and guidance for applying the equations in Chapter J of AISC 360-16 to HSS connections. As you can see below, the left column in black shows 360-10 / 14th Edition Manual and the new 360-16 / 15th Edition Manual is shown in blue text on the right.

The Limit State Tables serve as a transition key from 360-10 to 360-16 and will provide any limits of applicability for each connection as well as any end distance requirements. For each limit state, connection capacity equation references are shown with variable substitutions specific to HSS members, which is especially helpful when using yield line theory for plastification.

Overall, the usefulness of these new Limit State Tables should alleviate any heartache over the removal of the prescriptive tables for HSS connection design from the AISC manual. The new guidance on using the equations from Chapter J in AISC 360-16 will allow engineers to determine the capacity of connections whose geometry may not match those present in 360-10 and the design process more closely matches that of typical wide flange connections. Click to access these Limit State Tables which are available for FREE on the Steel Tube Institute’s website.

In January 2021, SE University welcomed back Kim Olson, PE, from Nucor and Steel Tube Institute, to present Navigating AISC 360-16 HSS Connection Design. Kim designated AfterHours Denver back in 2020 (https://afterhoursdenver.org/) for our SEU Speaker Inspires donation for the month and she has chosen to do the same in 2021.

Kim shared, “AfterHours Denver hands out over 400 lunches, water, socks and communion to the hungry and hurting every week in the park downtown. The smiles on the faces of the people we serve fills my cup while filling their bellies.”

Thank you, Kim, for helping structural engineers with your SE University session, and for your designation of AfterHours Denver as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

26 Jan 2021

Mental Fitness in 2021

A recent study by Oracle found that 78% of employees in 2020 were negatively impacted by their mental health. While 2020 may have been the most stressful year in recent history, 2021 offers the possibility of new habits, positive intentions, and boundless hope for improved work satisfaction.

As remote working continues for some and social distancing remains the norm in office environments, how can employees positively impact their mental health while remaining socially safe during the remainder of this pandemic and into an uncertain future? As it turns out, many companies are taking note of the mental health status of the workforce and developing new ways to offer emotional support for workers.

New technologies have scaled at a rapid pace to meet the mental and physical health needs of a socially distanced population. Apps such as Calm, Headspace and Insight Timer offer guided meditation, mindfulness tips, and calming music to improve sleep. For more active learners, MindDoc or Happify offer daily exercises and evaluations to identify ways to change your cognitive behavior.

Many workers have vowed to make positive changes to their health in 2021 and mental health deserves equal ground with physical health. With many gyms and sports programs across the country still closed or at reduced capacity, fitness apps such as Peloton, DownDog, All / Out Studio, or Aaptiv can fill in the gaps for missing workouts. Physical health certainly promotes mental health, so it is essential to maintain a healthy balance to see improvement.

Take time this year to invest in maintaining balance in all aspects of your health. Modern technologies are available and created specific for workers suffering from anxiety, burnout, depression, and loneliness. Many apps are available for free or offer free trials which can give you a window of opportunity to create a new, healthy habit in 2021.

In December 2020, SE University welcomed Mike Antici, PE, from Nucor / Steel Deck Institute, to present Steel Deck Design for Concentrated and Non-Uniform Loads. Mike designated Harvest Hope (https://www.harvesthope.org/) for our SEU Speaker Inspires donation for the month.

Mike shared that he selected Harvest Hope because it is “a local food bank providing food for South Carolina’s most vulnerable citizens – children, seniors, and rural residents who don’t have access to grocery stores. We also run our own emergency food pantries where anyone in need can get a week’s supply of groceries for free. Nucor is a contributor to Harvest Hope.”

Thank you, Mike, for helping structural engineers with your SE University session, and for your designation of Harvest Hope as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

31 Dec 2020

Zoom Meeting Etiquette for Professionals

2020 may be coming to a close, but the age of social distancing isn’t a thing of the past quite yet. As more states face second shutdowns, and holiday travel may have people meeting on the go, online video conferencing has become a new normal for professionals and engineers are not immune.

Video conferencing tools such as Zoom, Skype and Microsoft Teams are essential tools during this time of working remotely, but engineers should adhere to some basic etiquette rules to maintain their professionalism. First, as with typical office meetings, do your prep work ahead of time, and that now includes your own tech support. Services such as Zoom offer a way to test your settings before the meeting goes live at zoom.us/test. Skype also offers a way to test your call through their Echo / Sound Test Service in your contacts tab. Having all the kinks worked out of your audio/video settings before the meeting will avoid any embarrassing delays on your account.

Next, be sure to create a professional environment for your virtual meeting. Notice what lies behind you, but within your camera’s view. Your co-workers or clients should be spared any distractions which may be viewable through an open window in your office or other members of your household moving around during the call. If you are unable to meet in a quiet workspace, virtual backgrounds can be used to eliminate distractions. You should also dress appropriately and ensure proper lighting in the room so all attendees can see your face clearly throughout the meeting.

After the meeting has begun and all attendees have been introduced, be sure to keep your audio on mute to prevent any background noise from interrupting the speaker. When you are speaking, be sure to look into the camera rather than at your face so that you appear to be making eye contact.

As with an in-person meeting, you should avoid answering other emails or text messages during your virtual meeting. Although you may think you can get away with it, other participants may notice you seem distracted or dismissive. Be attentive and realize that non-verbal communication, such as head nods or hand raises, can be crucial to moving business along quickly when meeting virtually.

Unless you have disclosed to the host that you need to leave early, you should remain on the call until the host announces the completion of the agenda. If the meeting runs over the allotted time, you may politely interrupt if there is an appropriate pause from the speaker, or leave a comment in the chat feature, to inform the host that you have another obligation to attend to, and then you may need to follow up to see what was discussed during your absence.

Zoom, Skype, and Microsoft Teams all offer their own tips for attending and hosting virtual meetings, so be sure to check out their platforms to learn more about ways to improve communications when meeting virtually. While some businesses may return to a pre-Covid existence, many will continue to operate remotely in the future, so maintaining professional habits when meeting virtually will be a new skill employers require in their workforce.

What happens to a concrete mix when you add additional cement to the mix design? Most structural engineers would surmise that you would get a bump in concrete strength, but is that the only effect on the concrete mix? How can engineers specify a design that avoids excessive drying shrinkage? Are you familiar with the various components in a concrete mix design and their effect on the overall performance of the concrete?

In September 2020, Otto Schwarz, PE, SE, from Ryan Biggs | Clark Davis presented Concrete Mix Design for SE University. Otto reviewed the composition and curing process of structural concrete and explained the function and roles of pozzolans or supplementary cementitious materials and admixtures. He also advised on what to look for in a Concrete Mix Design Review and how to qualitatively predict the relative behavior of a concrete mix design.

In order to approximate the performance of comparative mix designs, Otto gave some guidelines as to the relative effects from varying components being added to the mix design. Watch this short video clip to hear Otto explain how the addition of these components affect the concrete mix:

As Otto explained, the varying components can affect the strength, slump, shrinkage, workability, etc. Knowing these relative effects, the engineer can approximate ways to manipulate the mix design with favorable results. Also, engineers can be more aware of the effects from any changes to the mix that were made in the field and better predict the result from those field changes.

In November 2020, SE University welcomed Mark D. Denavit, PhD, PE, from University of Tennessee – Knoxville, to present New Methods for Ponding Analysis of Open Web Steel Joist Roofs. Mark designated World Wildlife Fund (https://www.worldwildlife.org/) for our SEU Speaker Inspires donation for the month.

Mark shared, “I have a three-year-old son. We love watching nature documentaries together, especially ones by David Attenborough. I was inspired to select the World Wildlife Fund after watching David Attenborough’s recent film, A Life on Our Planet. It was amazing to see how much that planet has changed over the span of one lifetime. Also amazing was his vision for the future which I found inspiring and hopeful. I am happy to support efforts that align with that vision..”

Thank you, Mark, for helping structural engineers with your SE University session, and for your designation of World Wildlife Fund as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

24 Nov 2020

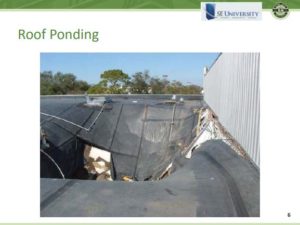

Strategies to Address Ponding Loads

What is the best way to avoid a potentially catastrophic roof collapse due to ponding instability? Once you have determined that ponding could be an issue for your roof design, what is the most efficient way to improve the design to ensure adequate strength and stiffness to resist ponding?

What is the best way to avoid a potentially catastrophic roof collapse due to ponding instability? Once you have determined that ponding could be an issue for your roof design, what is the most efficient way to improve the design to ensure adequate strength and stiffness to resist ponding?

In the November 2020 SE University session, Mark Denavit, PhD, PE, from the University of Tennessee, Knoxville, presented New Methods for Ponding Analysis of Open Web Steel Joist Roofs. Mark’s session reviewed the main roof ponding requirements from design standards and described the limitations of the method of ponding analysis given in Appendix 2 of the AISC Specification. Mark demonstrated how to use the SJI Roof Bay Analysis Tool to determine the stability of a simple roof system and explained the main factors influencing the ponding stability of open web steel joist roofs.

When possible, Mark recommended to first avoid developing ponding loads on roofs by providing adequate slope to a free draining edge. This can be achieved by sloping roof members or using tapered insulation or sloping fill. Mark helpfully noted that parallel chord joists with end supports at different elevations are more economical than providing pitch into the joist top chords.

When ponding must be evaluated, the SJI’s Roof Bay Analysis Tool can be used to quickly and easily determine whether the roof framing is sufficient to resist ponding. If the tool shows that the roof is inadequate, aim to stiffen the roof members to reduce the additional load caused by ponding, or strengthen the roof members to resist the additional load. If possible, you may consider adjusting the shape of the roof to reduce the additional loads from ponding, or you may need to use a combination of these adjustments to reach a stable roof design.