Structural strengthening with externally bonded FRP has grown in popularity in recent years and provides a viable option for strengthening reinforced concrete for seismic applications, remediations or retrofit of existing structures. Many products are available on the market, and design guidance has been included in building codes for a number of years. Are you aware of the benefits and limitations of this type of external reinforcement?

In the July 2021 SE University session, Mark Jarvinen, PE, from Simpson Strong-Tie, presented Design Methodology and Calculations using Fiber-Reinforced Polymer Systems. Mark covered the design philosophy presented in ACI 440.2R-17 and ACI 318 and explained the strengthening limitations of FRP. Mark walked through the design methodology for FRP strengthening of a reinforced concrete beam for shear and flexure, as well as improving reinforced concrete column strength with FRP confinement.

Mark reviewed important considerations when using FRP for shear strengthening of reinforced concrete beams. FRP has been shown to increase the shear strength of existing reinforced concrete beams by wrapping or partially wrapping the beam. The FRP fiber is oriented transverse to the longitudinal axis or perpendicular to shear cracks in the member. Mark noted that shear cracks must be epoxy injected before the addition of FRP in order to reestablish any aggregate interlock that has been lost due to the cracks. This is imperative in order to consider the contribution of the concrete when determining the combined shear strength of the member. However, depending on the quality of the workmanship for the crack repair, the engineer may want to consider the implication on the shear strength provided by the concrete during design. Mark noted these cracks should be repaired using a product that meets ASTM C881, Type IV criteria for such a load bearing application.

Three types of FRP wrapping schemes can be used for shear strengthening of RC beams: completely wrapped, 3-sided or U-wrapped, or 2-sided wraps. These can be continuous or discrete strips. Mark advised that discreet strips allow for moisture migration which can be essential when working with beams exposed to the elements. FRP as well as the primer used before its application are vapor barriers and will contain moisture within the element if used continuously.

Follow along, as Mark walks through a design example using discrete FRP U-wraps to increase the shear strength of a reinforced concrete beam according to the guidelines in ACI 440.2R-17 and ACI 318 by watching this short 4 minute video:

After Mark determines that the reinforced shear strength is greater than the shear demand on the member, he checks the shear strengthening limit to ensure the total shear strength provided by the steel plus the FRP is not greater than the criteria provided in ACI 318 for steel alone according to ACI 440.2R-17, Sec. 11.4.3. Lastly, he determines how far into the span the discrete strips are needed by plotting the shear diagram of the member to determine where the strips are no longer necessary. For further guidance, click here to access the full design example shared by Mark to learn more about the design calculations and limit checks needed to use FRP for shear strengthening of reinforced concrete beams.

Are you stuck in an empirical rut when it comes to locating control joints in your structural masonry walls? Control joints at 25 feet on center with standard joint reinforcement is typical for many engineering projects, however, some buildings warrant a closer look at minimizing the use of control joints in order to achieve a more efficient wall and a cost effective solution.

In August 2021, Sam Rubenzer, PE, SE, from FORSE Consulting, presented Movement Joints for Masonry – Structural Edition for SE University. Sam explored the role of masonry movement joints in structural masonry walls, as well as the movement properties of masonry materials and structural systems. He explained the purpose of joints, what to consider when locating them, and who is responsible for locating them according to the code.

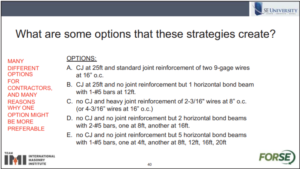

During the presentation, Sam gave an example with 5 options for horizontal reinforcement for the same basic wall design using the NCMA TEK guides 10-2D and 10-3. Using both the empirical approach and an engineered approach, the following 5 options were presented as viable options:

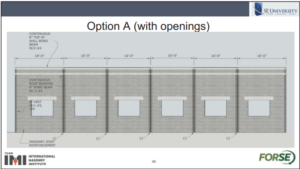

- Option A is a very commonly used empirical method for determining CJ spacing with typical joint reinforcement which most contractors would be very familiar with.

- Option B offers a similar CJ spacing while eliminating joint reinforcement in lieu of a single reinforced bond beam.

- Option C eliminates all control joints, but includes heavy joint reinforcement closely spaced.

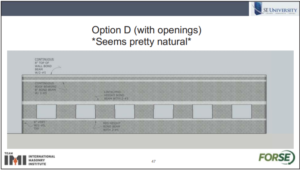

- Option D also has no CJs but includes 2 reinforced bond beams.

- Option E eliminates all CJs but includes 5 reinforced bond beams at various heights.

All of these options satisfy the need for horizontal reinforcement to control cracking for this basic structural masonry wall, however one option may be preferable over another depending on the contractor doing the work or the need for additional structural capacity of a longer shear wall with less control joints.

These additional options become even more beneficial when considering more complicated walls with openings. Walls with repeated large openings spaced closely together become less efficient with control joints located between each opening. Thus, a continuous reinforced bond beam makes more sense to eliminate the use of control joints between each opening. As you can see from these two slides, the second option makes good sense, and offers a wall with less overall maintenance costs and would most likely cost less to construct.

Control joints are certainly necessary in certain situations where stress concentrations are likely to accumulate such as corners, intersecting walls, or a wall with a change in height. However, in many cases, minimizing the number of control joints can produce a more cost efficient wall design that is easier to construct and maintain over the life of the structure.

In August 2021, SE University welcomed Sam Rubenzer, PE, SE, from FORSE Consulting, to present Movement Joints for Masonry: Structural Edition. Sam designated Fellowship of Christian Athletes (https://www.fca.org/) for our SEU Speaker Inspires donation for the month.

Sam shared “Fellowship of Christian Athletes is a good organization to provide support for students mind body and spirit. The organization especially encourages athletes to stay grounded in the teachings of Jesus, and put their faith in action while pursuing their goals in sports.”

Thank you, Sam, for helping structural engineers with your SE University session, and for your designation of Fellowship of Christian Athletes as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

In July 2021, SE University welcomed Mark Jarvinen, PE, from Simpson Strong-Tie, to present Design Methodology and Calculations using Fiber-Reinforced Polymer Systems. Mark designated Forgotten Felines and Fidos (http://www.forgottenfelines.org/) for our SEU Speaker Inspires donation for the month.

Mark shared “Animals have no voice to advocate for their welfare or express their suffering and neglect. There are so many domesticated animals that need help that charitable organizations can’t reach them all. I respect and want to help those in our society that care for neglected and abused animals that so desperately need assistance. I chose Forgotten Felines and Fidos because of their unselfish commitment to caring for displaced cats and dogs in northwestern Lehigh County.”

Thank you, Mark, for helping structural engineers with your SE University session, and for your designation of Forgotten Felines and Fidos as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

24 Sep 2021

References for Masonry Movement Joint Design

Whose responsibility is it to locate control joints within a masonry structure? When is it appropriate to eliminate vertical control joints in structural masonry walls? Movement joints often are overlooked for their importance to the integrity of masonry structures, and many times are inadequately addressed in typical notes or specifications rather than physically identified on structural plans.

In August 2021, Sam Rubenzer, PE, SE, from FORSE Consulting, presented Movement Joints for Masonry – Structural Edition for SE University. Sam explored the role of masonry movement joints in structural masonry walls, as well as the movement properties of masonry materials and structural systems. He explained the purpose of joints and what to consider when locating them, as well as who is responsible for locating them according to the code.

Sam suggested several NCMA TEK guides that are useful for engineers who need further guidance for designing movement joints in structural masonry walls. All of these guides are available for FREE download from NCMA and the links are included here for your reference.

- NCMA TEK Guide 10-1A Crack Control in Concrete Masonry Walls addresses various causes of cracking and crack control strategies.

- NCMA TEK Guide 10-2D Control Joints for Concrete Masonry Walls – Empirical Method provides guidance for typical masonry buildings using a more empirical approach to locating movement joints.

- NCMA TEK Guide 10-3 Control Joints for Concrete Masonry Walls – Alternative Engineered Method explores a more engineered approach to movement joints and horizontal reinforcement.

- NCMA TEK Guide 10-4 Crack Control for Concrete Brick and Other Concrete Masonry Veneers applies to cracks resulting only from internal volume change of the concrete masonry veneer and does not address cracking due to externally applied loads.

Additionally, Sam referenced The Masonry Society’s TMS 402/602-16 Building Code Requirements and Specifications for Masonry Structures which is referenced by the International Building Code 2018 and is available to purchase through the above link. This document is essential when designing masonry structures and, as Sam noted, makes clear the responsibility lies with the designer to “indicate type and location of movement joints on the project drawings.”

Properly designed movement joints and horizontal reinforcement are critical for successful, crack-free masonry structures. These resources can be used for simple, straightforward designs or to explore additional options for the design of movement joints when an empirical approach falls short on your next masonry project.

26 Aug 2021

Principles for Concise Technical Writing

When was the last time you reflected on your writing process for emails, reports, or client updates? Have you considered ways to improve how your audience may perceive your document? Writing is truly an artform, and technical writing requires great skill to engage and inform readers without being unnecessarily complex and difficult for readers to understand. Producing clear and concise documents can help communicate technical information effectively and improve your esteem with your readers or clients.

In October 2018, Janel Miller, from the University of Wisconsin at Madison, gave a presentation on Improving Clarity, Coherence, and Conciseness in Technical Writing. Janel reviewed how to prepare coherent documents, engage and persuade readers, and apply principles of concise writing to improve clarity.

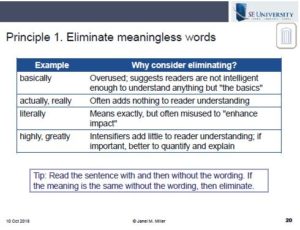

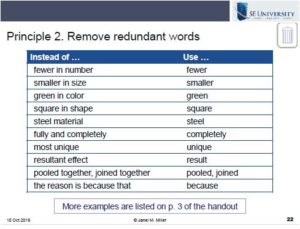

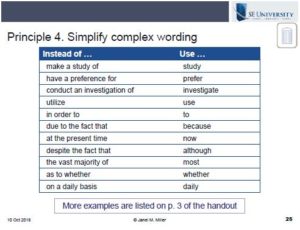

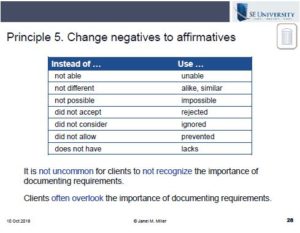

Janel gave excellent pointers on how to simplify writing to reduce the verbal complexity so readers can understand the technical complexity. She reviewed Joseph Williams’ five principles of concise writing from the text Style: Toward Clarity and Grace. These principles are

- Eliminate meaningless words

- Remove redundant words

- Delete what readers can infer

- Simplify complicated wording

- Change negative to affirmatives

After drafting the basic concepts of your document, take some time to edit using these basic principles to reduce wordiness and improve clarity. Most readers will appreciate a more concise version of your document which will improve your credibility with those readers.

Janel also provided helpful examples of these principles and ways to apply them in technical writing. Click on the following slides to print your copy for quick reference when preparing your own technical writings.

22 Aug 2021

Structural Fire Protection

Are you familiar with the significant changes and common failure modes that occur in a steel framed structure during a fire? For over a century, engineers have been using a prescriptive approach to protect steel structures and their occupants from a fire event. The International Building Code also permits the application of performance-based structural fire design to evaluate structural systems during a fire in a similar manner as other design loads are treated. Could any of your projects benefit from a structural fire engineering design rather than the typical prescribed fire protection?

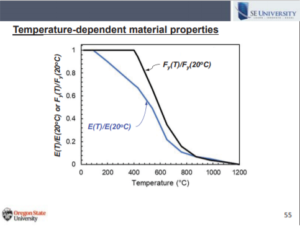

In the June 2021 SE University session, Erica Fischer, PhD, PE, from Oregon State University, presented Structural Fire Protection. Erica explained the difference between a prescriptive fire protection design and structural fire engineering. Erica qualitatively showed how steel strength and stiffness change with increasing temperature and how boundary conditions for beams and columns can change during a fire event. She also presented a case study showing the benefits of employing fire engineering on a steel framed structure.

Structural fire engineering becomes a complex endeavor because of the temperature-dependent material properties and the potentially changing boundary conditions throughout a fire. As you might expect, as the temperature increases, both the yield stress and ultimate stress are decreasing and the elastic modulus is decreasing, however they are not decreasing uniformly. Erica included the following slide which shows the complexity of these changing mechanical material properties. As you can see, the yield stress remains constant until about 400 degrees, but the stiffness decreases at a much lower temperature and they are not decreasing linearly.

Additionally, not all steel components have the same degradation patterns of material properties. Steel bolts, for example, respond differently than mild steel to thermal increases. Thus, predicting the behavior of connections can be very complex and the controlling failure modes at elevated temperatures will be different than those at ambient temperature. To hear Erica explain the changes to boundary conditions throughout a fire, watch this short 3 minute video:

During her presentation, Erica suggested engineers refer to ASCE’s Structural Fire Engineering MOP 138 book to learn more about performance-based structural fire engineering. This book is available on ASCE’s website for purchase as an e-book or in print. This reference provides guidance on calculated design of a structure to withstand the thermal load effects of fire, including performance objectives and analysis techniques to quantify the structural response to thermal increases.

In June 2021, SE University welcomed Erica Fisher, PhD, PE, from Oregon State University, to present Structural Fire Protection. Erica designated the Girls Build (https://girlsbuild.org/) for our SEU Speaker Inspires donation for the month.

Erica shared “Girls Build provides access and opportunity for young girls to engage with the building construction industry through hands-on learning experiences in the state of Oregon. These types of experiences can change the perception young girls have of the building construction industry and the perception of what careers are possible for them. As engineers, it is critical that we have diversity within our offices so that we can create solutions to societal issues that are applicable to all members of a community.”

Thank you, Erica, for helping structural engineers with your SE University session, and for your designation of Girls Build as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

Effective communication is a skill that is often undervalued in the workplace. We have years of training and multiple degrees to learn our trade, but how much time along the way has been directed at learning to deal effectively with others? Typically, we focus all our energy on learning concrete design techniques (pun intended), but how do we develop our soft skills, in order to promote ourselves and our careers and be productive members of a team? How do we relate to others in an increasingly diverse workplace environment, and learn to thrive with others who may have a different personality type?

In the August 2016 session of SE University, Annie Kao, PE with Simpson Strong-Tie, gave a presentation on Effective Communication Skills for Workplace Conversations and Meetings. One of the main topics that Annie discussed was the benefit of cultivating a reward-state environment as opposed to a threat-state environment in our workplace.

When employees feel they are in a reward-state, they are able to work more effectively, both independently and as part of a team. Annie provided a useful tool to assess which values create a reward-state, and how we can use this information to be more intentional in the way we relate to our coworkers. The online SCARF Assessment looks at five domains that each of us finds more or less valuable depending on our personality – Status, Certainty, Autonomy, Relatedness, and Fairness. After completing the online assessment, the results include a brief description of each domain and how it affects our behavior.

Annie noted that, without knowing what is valued by our peers, we could inadvertently be placing them in a threat-state. For example, managers who really value autonomy may think that they are empowering their team members by giving them the freedom to work without restriction. However, if members of the team value certainty, this level of freedom may place them in a threat-state due to the lack of feedback or guidelines to follow. By understanding our own needs and the needs of others, we can be more cognizant of the way we respond and what type of feedback we give to others. This helps create an atmosphere where everyone feels valued for their contributions.

Annie also provided another resource that helps identify our tendencies toward particular behavior traits. The online DISC Assessment categorizes behavior into four groups – Dominance, Influence, Steadiness, and Conscientiousness. Based on our tendencies toward particular traits, we can be more self-aware of our own strengths and weaknesses, and learn to appreciate the tendencies of others and how their differing personalities can impact the team.

Using these assessment tools in the workplace, we can make intentional changes to our behavior and become more aware of the behavior tendencies of others in order to create a more efficient and enjoyable work environment. Sharing these tools with coworkers can help improve teamwork and elevate our respect for one another.

In May 2021, SE University welcomed Emily Guglielmo, SE, from Martin/Martin Consulting Engineers, to present Serviceability for the Practicing Engineer. Emily designated the SEAONC DEI Endowment Fund (https://www.seaonc.org/page/SEAONCDEI) for our SEU Speaker Inspires donation for the month.

Emily selected the Structural Engineers Association of Northern California (SEAONC) DEI Endowment as it’s a new and innovative way to put words and promises of the past year into action. The Endowment is a funding vehicle that will assure the long-range financial future of a restricted fund to support entities, programs, scholarships and initiatives focused on Diversity/Equity/Inclusion (DEI) in Structural Engineering.

Thank you, Emily, for helping structural engineers with your SE University session, and for your designation of the SEAONC DEI Endowment Fund as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.