When does a shear wall turn into a wall pier? Have you struggled in the past to decide whether the short wall segments that surround a loading dock opening qualify as a wall pier or a column frame element in your tilt-up wall design? Each type of wall element demands different detailing requirements, and more than one element can be found in the same wall panel.

In the July 2019 SE University session, John Lawson, PE, SE, from Cal Poly – San Luis Obispo, presented Engineering Tilt-Up: Design Provisions Born from Past Experience. John reviewed how past failures have influenced current design practices and explained the implementation of current slender wall provisions and how to classify wall elements. He also covered wall anchorage forces and how they get transferred into the diaphragm and potential issues with both steel and wood deck roofs.

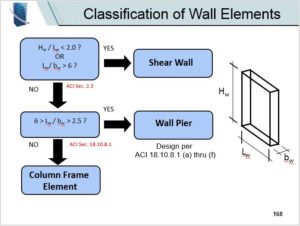

John helped clarify how to classify wall elements in tilt-up wall construction. Using the following flow chart, walls can be classified based on their length and thickness.

Once the wall has been classified as a shear wall, wall pier or column frame, the element can then be designed based on the applicable provision in ACI. Wall pier elements are a recent addition to ACI 318, beginning in 2011, and are now referenced in ACI 318-14 in section 18.10.8. Using the correct wall classification will ensure your tilt-up designs meet the detailing requirements in the code and perform in the way you intend for lateral resistance.

26 Jul 2019

2018 National Design Specification Changes

Have you reviewed the upcoming changes in the 2018 National Design Specification? Many changes resulted from changes to other reference standards, and it is important to note their impact on future wood design.

In the June 2019 SE University session, Lori Koch, PE, from American Wood Council, presented 2018 National Design Specification (NDS) Changes. Lori outlined and explained the changes included in each chapter and addressed how the wind load increases in ASCE 7-16 affected the NDS provisions.

Among the changes were new provisions for withdrawal design values for Roof Sheathing Ring Shank nails, as well as new design provisions for fastener head pull through values, both in response to the significant increases in Component and Cladding wind pressures in ASCE 7-16. Other significant changes include the addition of a volume factor, Cv, for structural composite lumber and revisions to the Cross Laminated Timber deflections provisions to be consistent with the terminology used in ANSI/APA PRG 320-2017.

In case you missed Lori’s presentation, or if you want to print a quick reference of the changes to the 2018 NDS, click here to access the AWC’s publication highlighting all relevant additions or alterations. At the end of the article, AWC has provided an Appendix: Summary of Changes, which details all the changes by chapter.

26 Jul 2019

Box Beam Design in Cold-formed Steel

Have you struggled to find a good reference for the design of built-up members in cold-formed steel? The code tends to address some assemblies used in a few applications, but often leaves the engineer to determine how design equations may need to be modified for dissimilar shapes or configurations.

In the May 2019 SE University session, Roger LaBoube, PhD, PE, from Missouri University of Science and Technology, presented Built-Up Member Design (Cold-Formed Steel). During the session, Roger reviewed the applicable cold-formed steel standards for framing members vs. other cold-formed applications, discussed economical solutions for stud packs, and walked through a design example of a built-up box beam that is not specifically enabled by the current design standards.

Perhaps the most anticipated topic in the session included Roger’s rationale for using AISI S100 as it can apply to a built-up box beam section. To hear Roger’s explanation and his discussion regarding the changes needed to use the applicable equations in D1.1, click on the video below:

For further clarification, the CFSEI Tech Note TN G104-14 – Welded Box-Beam Flexure Design can be purchased from the link, or it is available as a free download to CFSEI members.

21 Jun 2019

Benefits of Masonry Lintels

Masonry lintels have been used throughout history and have withstood the test of time in many instances. Why is the masonry lintel such an efficient design compared to other available materials? You might think higher strength values can be achieved using other materials, however, masonry lintels built integral with the wall can produce robust and efficient designs in most cases.

In the April 2019 SE University session, Cathleen Jacinto presented Lintels for Masonry Walls. Cathleen reviewed the behavior and load distribution of lintels and masonry walls with openings and discussed practical design and detailing strategies to achieve high performing lintels. Cathleen also explained the advantages of analyzing masonry walls with finite element software.

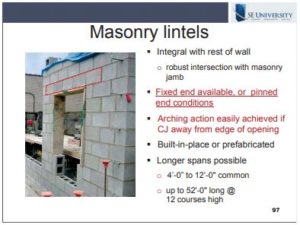

As necessary elements within a masonry wall, lintels can be built integral with the wall, or be constructed using other materials. Cathleen reviewed the benefits of using masonry for lintel design as shown on the following slide:

Masonry lintels are typically more easily constructed since there is less coordination between disciplines and the masonry lintel ties in easily with the masonry jamb. Because of this fixity between the lintel and the jamb, a masonry lintel offers a more fixed-end condition than lintels using other materials which increases the strength of the overall wall.

Cathleen strongly recommended locating control joints away from the openings, so that arching action can be achieved. Perforated shear walls using masonry lintels can have three times the shear capacity compared to a masonry wall with control joints at the openings due to this increase in strength from arching action. With the option of prefabricated masonry lintels, longer spans are achievable making masonry lintels on par with other alternatives. Also, there is no concern for differential movement between the wall and lintel, as there may be with dissimilar materials, and there is less likely to be issues with thermal breaks.

Masonry lintels provide robust and heavy load resistance, which can enhance the performance of the masonry wall. Recent advances in shoring techniques and constructability make it an attractive option, even when shoring or prefabrication may be required. Removing some of the concerns about differential movement can add to the reasons why you may want to consider designing a masonry lintel with your next masonry wall.

In May 2019, SE University welcomed Roger LaBoube, PhD, PE, from Missouri University of Science and Technology, to present Built-Up Member Design (Cold-Formed Steel). Roger designated the Leukemia and Lymphoma Society (https://www.lls.org/) for the SEU Speaker Inspires donation of the month.

Roger shared: “On June 7, 2003, our daughter Jennifer married Russ. The wedding was a wonderful family event and Karen and I were both extremely happy for Jennifer and Russ. Four short months later, Russ was diagnosed with Hodgkins Lymphoma Stage 4B. After 10 months of treatments, Russ’ Hodgkins was forced into remission. Obviously, Karen and I were elated to learn of this news. However, in June 2005, Russ was diagnosed with leukemia. Following more chemotherapy and a stem cell transplant, the leukemia is now in remission. I chose to support LLS to honor both Russ and Jennifer for their fighting spirit and to help others who are also fighting so hard to defeat their cancer. Our family has benefited first hand from both the research and the patient services of the Leukemia and Lymphoma Society.”

Thank you, Roger, for helping structural engineers with your SE University session, and for your designation of the the Leukemia and Lymphoma Society as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

Don’t miss a career changing event – Gain insight from a leader in engineering career development and communication strategies!

Get Noticed, Find More Meaning, and Make a Bigger Impact at Work Through Job Crafting

Speaker: Stephanie Slocum, PE

Founder at Engineers Rising, LLC

Event Hosted by SE Impact

To get free access to the recording, simply register for our SE Dynamics newsletter below.

Join us for a special opportunity to improve your standing and satisfaction at work.

SE IMPACT in conjunction with ENGINEERS RISING offers a Complimentary session, when we welcome Stephanie Slocum, PE, from Engineers Rising, LLC, to present…Get Noticed, Find More Meaning, and Make a Bigger Impact at Work Through Job Crafting.

Session Description:

Job crafting leads to a more impactful and satisfying career. In this webinar, you’ll learn what job crafting is and how you can use it both for yourself and for those you manage and mentor. You’ll hear the story of how our speaker, Stephanie Slocum, accidentally stumbled upon this concept, and then used it to earn a promotion, write a book, and start a company. At the end of this presentation, you’ll do an exercise where we’ll guide you the process so you can start applying it when you go to work tomorrow.

Access the session recording

To view the recorded session, including Q&A, please enter your information below. After submitting your information you’ll be redirected to the recording page, and you’ll start receiving our SE Dynamics Newsletter on a monthly basis.

If you have any questions, please contact:

Brian Quinn, PE – (616) 546-9420

[email protected]

Note: Session was conducted live on June 12, 2019

29 Apr 2019

Getting Ahead at Work and in Life

Are you struggling to achieve the goals you’ve set for yourself in the workplace? Do you feel like you aren’t where you want to be careerwise, and don’t know the steps to create the success you crave?

I recently came across this insightful article from Time Management Ninja, To Get Ahead, Do 21 Things that Others Don’t. Combined, the 21 tips offered a recipe for changing patterns that may be holding you back from reaching your potential. All of the tips may not apply to you, however, the overall advice is a good reminder that there is no quick fix for things that require hard work and sacrifice. Sometimes, the hard work required may be more introspection and self-evaluation to change your own thoughts and patterns.

Successful careers don’t happen overnight. They are the combination of years of diligent work combined with making sound, daily decisions that move you one step closer to your goals. One of the most important tips from the TMN article suggests to Learn New Things. A commitment to lifelong learning is a trademark of highly successful people. Be committed to learning new things, especially when those ‘new things’ will add to your success in the workplace and in life!

28 Apr 2019

Avoiding Problematic Vibrations

Have you been involved in the remediation of a building experiencing vibration issues? Do you consider vibrations during your structural analysis to ensure the building occupants will feel comfortable in the structure? ASCE 7 explicitly states that “Structural systems, and members thereof, shall be designed to have adequate stiffness to limit deflections, lateral drift, vibration, or any other deformations that adversely affect the intended use and performance of buildings and other structures.” Vibration is an important serviceability issue, and since vibration effects on humans can be subjective, it can sometimes be difficult to foresee.

In the March 2019 SEU session, Geoff Blumber and Ravi Ozarker, PE, P.Eng., from Hexagon PPM, presented Avoiding Vibration Issues in Your Structure. During the session, Geoff explored the types of vibration and vibration sources which should be considered during design, and Ravi examined several strategies for improving dynamic analysis results using structural software, ways to avoid vibration issues during design, and remediation methods.

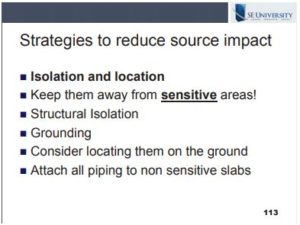

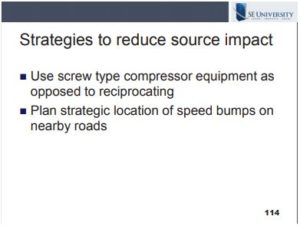

Ravi stressed that the best way to avoid vibration issues is identifying potential sources of vibration early in the planning phase and then plan strategies to reduce their impact on the structure. Most importantly, he offered the rule of thumb that the mass of the supporting structure be 3 times the mass of vibrating machinery to reduce potential vibration issues. He also offered several helpful tips to reducing source impact as shown on the following slides:

In existing structures, remediation may be complex to reduce any existing vibration issues. Ravi suggested a thorough vibration analysis of the existing structure, and then a new analysis including any potential remediation methods to be sure your proposal will reduce vibrations. Before more expensive damping-type solutions are explored, Ravi suggested increasing the stiffness of the structure to dampen vibrations or increasing the mass to dissipate vibrations. Some solutions included using ceiling hangers, floating floors, or neoprene pads or spring isolators for problematic equipment.

As structures become more and more optimized and floor layouts span longer and are lighter than previous floors, vibrations will continue to be problematic. With early planning and proper structural analysis, vibrations issues can be avoided, thus pleasing our clients and building owners.

In March 2019, SE University welcomed Geoff Blumber and Ravi Ozarker, PE, P.Eng., from Hexagon PPM, to present Avoiding Vibration Issues in Your Structure. Geoff designated the James Mirabal, P.E. Endowed Scholarship in Civil, Architectural and Environmental Engineering at the University of Texas at Austin (https://endowments.giving.utexas.edu/james-mirabal-p-e-endowed-scholarship-in-civil-architectural-and-environmental-engineering/) for the SEU Speaker Inspires donation of the month.

Geoff shared: “During my time at UT, Jason Mirabal was not only a classmate, but also a friend. His father, James is not only a PE but also a 1st generation college graduate who inspired his children to plan and persevere in their efforts to fund and complete their college degrees. His positive example inspired not only his children but also their classmates (including myself as the first in my family to attend college). This endowment was established to pay forward that inspiration and persevering example to assist others that are the first in their family to attend college. Any 1st generation college students pursuing a degree in Civil or Architectural Engineering from the University of Texas is eligible to apply.”

Thank you, Geoff, for helping structural engineers with your SE University session, and for your designation of the the James Mirabal, P.E. Endowed Scholarship in Civil, Architectural and Environmental Engineering at the University of Texas at Austin as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

14 Mar 2019

ASCE Offers New “Career by Design” Online Portal

ASCE has recently launched a new online platform available to its members designed to aid young engineers in career development. Career by Design was launched earlier this year and offers society members access to a wealth of targeted content, tools, tips, and opportunities for advancement. Login and check out relevant discussion boards, skills coaching, and advice on achieving licensure. Connect with other ASCE Younger Engineers and become a voice within the profession.

Also, included in this platform is Mentor Match which pairs the user with an expert who can guide you in the right direction. After setting up your profile, you can easily follow the steps outlined by ASCE to gain valuable advice and insight from a well-matched senior engineer.

Getting involved in the profession may seem intimidating at first, however this new online portal can get you plugged in and offer insight when career-oriented questions arise. Don’t miss out on this benefit available free to all ASCE members!