Effective communication is a skill that is often undervalued in the workplace. We have years of training and multiple degrees to learn our trade, but how much time along the way has been directed at learning to deal effectively with others? Typically, we focus all our energy on learning concrete design techniques (pun intended), but how do we develop our soft skills, in order to promote ourselves and our careers and be productive members of a team? How do we relate to others in an increasingly diverse workplace environment, and learn to thrive with others who may have a different personality type?

In the August 2016 session of SE University, Annie Kao, PE with Simpson Strong-Tie, gave a presentation on Effective Communication Skills for Workplace Conversations and Meetings. One of the main topics that Annie discussed was the benefit of cultivating a reward-state environment as opposed to a threat-state environment in our workplace.

When employees feel they are in a reward-state, they are able to work more effectively, both independently and as part of a team. Annie provided a useful tool to assess which values create a reward-state, and how we can use this information to be more intentional in the way we relate to our coworkers. The online SCARF Assessment looks at five domains that each of us finds more or less valuable depending on our personality – Status, Certainty, Autonomy, Relatedness, and Fairness. After completing the online assessment, the results include a brief description of each domain and how it affects our behavior.

Annie noted that, without knowing what is valued by our peers, we could inadvertently be placing them in a threat-state. For example, managers who really value autonomy may think that they are empowering their team members by giving them the freedom to work without restriction. However, if members of the team value certainty, this level of freedom may place them in a threat-state due to the lack of feedback or guidelines to follow. By understanding our own needs and the needs of others, we can be more cognizant of the way we respond and what type of feedback we give to others. This helps create an atmosphere where everyone feels valued for their contributions.

Annie also provided another resource that helps identify our tendencies toward particular behavior traits. The online DISC Assessment categorizes behavior into four groups – Dominance, Influence, Steadiness, and Conscientiousness. Based on our tendencies toward particular traits, we can be more self-aware of our own strengths and weaknesses, and learn to appreciate the tendencies of others and how their differing personalities can impact the team.

Using these assessment tools in the workplace, we can make intentional changes to our behavior and become more aware of the behavior tendencies of others in order to create a more efficient and enjoyable work environment. Sharing these tools with coworkers can help improve teamwork and elevate our respect for one another.

In May 2021, SE University welcomed Emily Guglielmo, SE, from Martin/Martin Consulting Engineers, to present Serviceability for the Practicing Engineer. Emily designated the SEAONC DEI Endowment Fund (https://www.seaonc.org/page/SEAONCDEI) for our SEU Speaker Inspires donation for the month.

Emily selected the Structural Engineers Association of Northern California (SEAONC) DEI Endowment as it’s a new and innovative way to put words and promises of the past year into action. The Endowment is a funding vehicle that will assure the long-range financial future of a restricted fund to support entities, programs, scholarships and initiatives focused on Diversity/Equity/Inclusion (DEI) in Structural Engineering.

Thank you, Emily, for helping structural engineers with your SE University session, and for your designation of the SEAONC DEI Endowment Fund as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

When considering drift limits, how conservative are you when selecting your Mean Recurrence Interval wind load? Do you typically use the nominal wind speeds from the maps provided in ASCE 7 and consider those to be conservative for serviceability? Engineers can use their judgment to best decide which MRI is appropriate for any given project, and in many cases, a less restrictive MRI might be best suited for drift evaluation.

In the May 2021 SE University session, Emily Guglielmo, SE, from Martin/Martin, presented Serviceability for the Practicing Engineer. Emily explained the current serviceability requirements that are codified and addressed key serviceability concerns for various building materials. Emily discussed practical limits for both vertical and horizontal deflections and the need for engineering judgment in serviceability considerations.

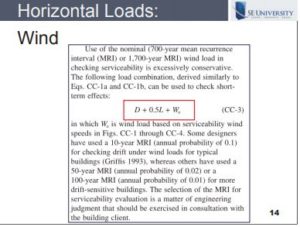

For horizontal loads, Emily specifically addressed drift due to wind since seismic deflections are typically controlled by life safety considerations. Wind, however, is a daily phenomenon for which a building should be properly designed to handle appropriate deflections without resulting damage to the structure or its finishes. Emily noted that in the Commentary to Appendix C in ASCE 7, the mean recurrence interval (MRI) is addressed for use in determining deflections for serviceability, as shown on the slide below.

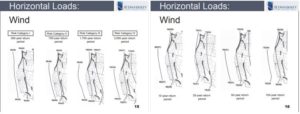

Equation CC-3 introduces a term, Wa, which does not appear in the standard, but is rather specific to the commentary. This Wa term is a wind load based on serviceability wind speeds from Figures CC1-CC4 which include wind speeds for MRIs of 10, 25, 50, and 100-year returns. Emily included comparisons between the wind speed maps from the standard to compare to the maps in the commentary.

As shown in the slides, the maps included in the commentary show significantly lower wind speeds and the commentary explicitly states that the “selection of the MRI for serviceability evaluation is a matter of engineering judgment…” Thus, engineers may use a less conservative MRI for serviceability considerations depending on the needs of the client, the materials in use, and the occupancy of the building, and the commentary implies that this is entirely reasonable. Of course, the designer may still opt to use the full nominal wind speed specified in Chapter 26 of the standard as the most conservative option for drift determination.

For some drift sensitive buildings or buildings with brittle finishes, a more conservative MRI would be sensible, however, the availability of the additional maps in the commentary are especially useful for the engineer who wishes to exercise more precise judgment from project to project.

18 Jun 2021

Determining Blast Design Pressures

Government facilities often require specialized design for blast loads, but some commercial buildings and municipal structures may also be deemed mission critical and need a blast-resistant design. Are you able to determine the design blast load when given a specified charge weight?

In the March 2021 SE University session, Aldo E. McKay, PE, from Protection Engineering Consultants, presented Blast-Resistant Design of Buildings. Aldo shared references and resources available for blast protection of buildings and reviewed the basics of modeling structural systems and components under blast loads. He also explained the blast loading performance objectives and blast loading requirements for different market sectors.

Aldo ran through a quick example to explain the process for determining the design loads on a building when provided with the charge weight and standoff distance of a building for an engineer that may not have access to any specialized software. This process uses charts initially developed by Kingery and Bulmash from spherical blasts in free air, and have been scaled to represent a hemispherical surface burst. To watch Aldo explain this process, click here.

Aldo mentioned that these curves are available in ASCE 59-11 Blast Protection of Buildings which is available for purchase from ASCE. Using the curves, Aldo was able to establish the design incident pressure and incident impulse to use for the blast design on this project. These incident pressures can then be used to design the roof elements or side wall structural elements. This same process can be used to determine the reflective pressure and reflective impulse. These charts can be especially useful for the engineer who does not have specialized software or just needs a quick estimate for design pressures for blast loading.

18 Jun 2021

“SEU Speaker Inspires” Organization of the Month: UDistrict Foundation Mentoring Program

In April 2021, SE University welcomed Ashley Cagle, PE, SE, from WoodWorks, to present Structural Engineering of Light Frame Wood Over Concrete Podium Structures. Ashley designated UDistrict Foundation Mentoring Program (https://udistrictpt.com/nonprofit-foundation/foundation-mentoring-info/) for our SEU Speaker Inspires donation for the month.

Ashley shared, “The Foundation’s mission is to ‘help children live healthy, productive lives and dream great dreams.’ Through the mentorship program, students, primarily from Title 1 schools in the greater Spokane area, are matched to the specific interests, background, and passions of volunteer mentors, resulting in long-lasting, rewarding relationships. Over the past year of disruptions, the need for steady, reliable relationships in children’s lives has only been highlighted. I have been a mentor with the UDistrict Foundation for the past year and a half and strongly believe in the value of these types of community-oriented, cross-generational relationships.”

Thank you, Ashley, for helping structural engineers with your SE University session, and for your designation of UDistrict Foundation Mentoring Program as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

In March 2021, SE University welcomed Aldo E. McKay, PE, from Protection Engineering Consultants, to present Blast-Resistant Design of Buildings. Aldo designated No Kid Hungry (www.nokidhungry.org) for our SEU Speaker Inspires donation for the month.

Aldo shared, “The ongoing pandemic has impacted all of us in different ways. One of the most severely and negatively impacted groups are kids in low-income communities. Many of the parents of these kids have lost their jobs and these kids often rely on school meals as their only source of food and nutrition. As a result of school closures, many of these low-income families have been left with no means to feed their kids. With our support, No Kid Hungry is committed to feeding kids in these communities to ensure every kid gets three meals a day. I think this is a great cause and something that all of us in a position to help should consider doing.”

Thank you, Aldo, for helping structural engineers with your SE University session, and for your designation of No Kid Hungry as our SEU Speaker Inspires Organization of the Month!

SE University began the SEU Speaker Inspires program in 2015 as a way to “pay it forward”, enabling our speakers to designate a charity/organization of their choice for SE University to make a donation to help improve our world.

20 May 2021

SE Solutions Provides Scholarships to 3 MSCE Structures Students from Purdue University (2021)

SE Solutions was pleased to recently present scholarships to three Purdue University Structures students to help defray the cost of their education. Mriganabh Boruah, Sarah Bowlin, and Heyi Feng were the recipients of the awards. This is the ninth year that SE Solutions has offered the scholarships.

SE Solutions was pleased to recently present scholarships to three Purdue University Structures students to help defray the cost of their education. Mriganabh Boruah, Sarah Bowlin, and Heyi Feng were the recipients of the awards. This is the ninth year that SE Solutions has offered the scholarships.

Mriganabh Boruah is from Assam, India. He received his bachelor’s degree from the National Institute of Technology Karnataka, Surathkal in 2018 and will be defending his master’s thesis in spring 2021 with a specialization in structural engineering. He had the opportunity to work as a teaching assistant for CE297-Statics for 2 semesters and has worked in the field of non-linear soil-structure interaction in nuclear power plants. His thesis is focused on reducing the computational time in brittle cracking analysis using Adaptive Multi-Time Step Decomposition. He has a job lined up with a structural engineering firm based out of Tulsa, OK and looks forward to being a part of a challenging industry.

Sarah Bowlin graduated with her bachelors degree in civil engineering from Oklahoma State University in May 2019. She plans on graduating with her masters degree from Purdue University in December 2021. She will be staying at Purdue to pursue a PhD in Civil Engineering. Sarah has had the goal of becoming a structural engineer since she was in high school and had the opportunity to take a variety of pre-engineering classes. At Oklahoma State, she was very involved with the Concrete Canoe Team, which sparked her interest in concrete structures. She enjoys learning about the different behaviors and applications for structural concrete, as well as all the other structural materials. She is currently a graduate research assistant focusing on the behavior of unbonded and bonded post-tensioned concrete bridge girders. After finishing school, she would like to find a challenging and rewarding job at a structural engineering firm.

Heyi Feng received his bachelor’s degree in civil engineering at Portland State University in 2019 and will complete his MSCE study with specialization in structural engineering at Purdue University in August 2021. Heyi has been working as a research assistant. His research focuses on finite element analysis of API 12F tanks, performing failure modes determination and fitness-for service analyses. He is also currently working as an engineering intern at Baker Consulting Group. Heyi is hoping to start his career with a firm that allows him to design innovative structures right after his graduation from Purdue.

SE Solutions would like to congratulate each recipient and wish them future success in their fields of study as structural engineers.

26 Apr 2021

Back in the Habit: Returning to the Office

Depending on where this newsletter finds you, you may or may not be back to your pre-Covid work routine. From state to state, mandates and guidelines have affected each of us differently, but without a doubt, many employees will soon find themselves returning to working from an office. These returns may be staged or staggered in the beginning or companies may jump right back to full time on-site staffing. In whatever situation you find yourself, here are a few tips to ease the transition from working remotely to in-person.

Start the adjustment now. Once you have received notice that your employer intends to return workers to the office, begin making small adjustments to your work-from-home routine to mimic your normal commuting habits. This may include rising earlier, eating breakfast or exercising as you would before heading to the office. Be sure to communicate any concerns with your supervisor so any issues can be addressed before the target return date. Any proactive steps can lessen the shock of a complete upheaval in your routine.

Manage your expectations. This is a unique situation for everyone involved, including your supervisor and your company’s leadership. Adopting a flexible mindset can minimize any frustrations that may arise from changing corporate guidelines and protocols. Keep communication open with your superiors, but also be patient to allow for any kinks to be ironed out during the transition period.

Respect your co-workers boundaries. Everyone has had a different experience over the past year. Some have been deeply and personally affected by this pandemic while others may have only noticed a small disruption in their daily life. Opinions are many and varied over what has transpired within our country and probably within your company, but we can each move forward with mutual respect between us. Some co-workers may feel comfortable socializing in close contact while others may not, but we must value the contribution of each team member equally, and allow for individual liberties to make all feel comfortable.

Coming together again may elicit a range of emotions, and transitions can be difficult at the best of times. However, if everyone can strive to remain thoughtful throughout the transition, any anxiety present may dissipate once we start moving toward a new and exciting ‘normal’ in our everyday office environment.

26 Apr 2021

Design Resources for Blast-Resistant Buildings

Does your engineering firm find itself needing to know more about the design of buildings for blast-resistance? Are you aware of the many available resources developed by a variety of public or government agencies which provide guidance on assessing risk level and threats for commercial or government buildings or determining required blast loads for design?

In the March 2021 SE University session, Aldo E. McKay, PE, from Protection Engineering Consultants, presented Blast-Resistant Design of Buildings. Aldo shared references and resources available for blast protection of buildings and reviewed the basics of modeling structural systems and components under blast loads. He also explained the blast loading performance objectives and blast loading requirements for different market sectors.

Aldo shared some necessary resources for the engineer who may be new to the blast-resistant design of buildings. First, he mentioned FEMA 426 Reference Manual to Mitigate Potential Terrorist Attacks Against Buildings, FEMA 427 Primer for Design of Commercial Buildings to Mitigate Terrorist Attacks, and FEMA 428 Primer to Design Safe School Projects in Case of Terrorist Attacks. Specifically, FEMA 426 gives an overview of physical security design concepts and the Threat and Vulnerability Risk Assessment (TVRA) process.

When designing airports, engineers may use TSA guidelines and several reports put out by the Program for Applied Research in Aiport Security (PARAS) including PARAS 0014 Blast Mitigation Strategies for Non-Secure Areas of Airports and PARAS 0028 Recommended Security Guidelines for Airport Planning, Design, and Construction. Aldo noted these reports include some valuable guidance as far as explosive weight data and standoff distances.

Aldo highly recommended ASCE 59-11 Blast Protection of Buildings. This document is available for purchase from ASCE and includes a comprehensive overview of the current practice in the analysis and design of structures for blast-resistance. It offers guidance on performance objectives and response criteria as well as modeling and detailing for blast-hardening. Aldo noted that many of the government agencies are now referencing ASCE 59-11.

As far as government standards, Aldo highlighted The Risk Management Process for Federal Facilities: An Interagency Security Committee Standard which is used for federal courthouses, FBI Buildings and other GSA facilities, as well as Physical Security and Resiliency Design Manual for the physical security design of VA facilities. For the Department of Defense, the United Facilities Criteria (UFC) 04-20-01 DoD Security Engineering Facilities Planning Manual and the UFC 4-010-01 DoD Minimum Antiterrorism Standards For Buildings.

Most of these documents are available as a free download from the links provided. These available resources should be a helpful reference to engineers tackling projects which may need a TVRA or are designated to require a blast analysis by any government agency. Some government resources may have distribution limitations.

25 Mar 2021

The New ASCE Code of Ethics

Are you a member of ASCE? You may be aware that ASCE has recently adopted a new Code of Ethics for its members which is the first comprehensive change to the code since 1974. Although the new guidance applies only to its membership, the document often influences states’ ethics laws which would then apply to all licensed engineers in that state. Thus, the changes may have far reaching effects in years to come.

In the February 2021 SE University Ethics Session, Matthew R. Rechtien, PE, Esq., from Walter P Moore, presented Engineering Ethics Update: The New Model Code. Matt explained ASCE’s stated rationale and goals for the changes made to their Code of Ethics. He also reviewed what was added or removed from the code and what changes were made and the implications of those changes to practicing engineers.

In order to truly assess the vast difference between the old Code of Ethics and the new document, it would be best to read through both versions of the code to be familiar with how the document has morphed from a canon based model to a new, more concise code. The ASCE Code of Ethics page includes the full version of the new Code of Ethics as well as a link to the previous version. Click here to access the previous version of the Code of Ethics, and to download and print the new Code of Ethics that was adopted by ASCE in October 2020 you can click here.

After reading through both documents, it is clear that much has changed. ASCE reduced the verbiage by about 75 percent. The new Code uses positive language rather than prohibitions and categorizes rules in a “Stakeholder” model. The 5 stakeholders in order of priority are: Society, Natural/Built Environment, Profession, Client, and Peers. Within any given category, there is no priority amongst the stated rules. However, ASCE expressly states that the highest responsibility shall be rule 1a, which states “Engineers, first and foremost, protect the health, safety, and welfare of the public.”

There are several noteworthy changes/additions to the new Code, the most significant being a new ‘duty to report’ any violations of bribery, fraud, or corruption. While the previous version stated the engineer ‘shall act with zero tolerance for bribery, fraud or corruption,’ the new Code implements a mandatory duty to “report violations to the proper authorities.” Also, there is new language to ensure health and safety in the workplace and a stronger obligation for engineers to adhere to the principles of sustainable development.

While ASCE has aimed to provide a more “useable and enforceable” code of conduct, Matt noted that law tends to be based on precedence and interpretation by the courts. This new Code may induce members to require further clarification from ASCE in order to ensure compliance since there is a lack of legal precedence since the adoption of these new rules.